10ml/Bottle Soldering Flux Liquid Aluminum Metal Electronics Copper Soldering Flux No Water Cleaning 18650 Battery Soldering

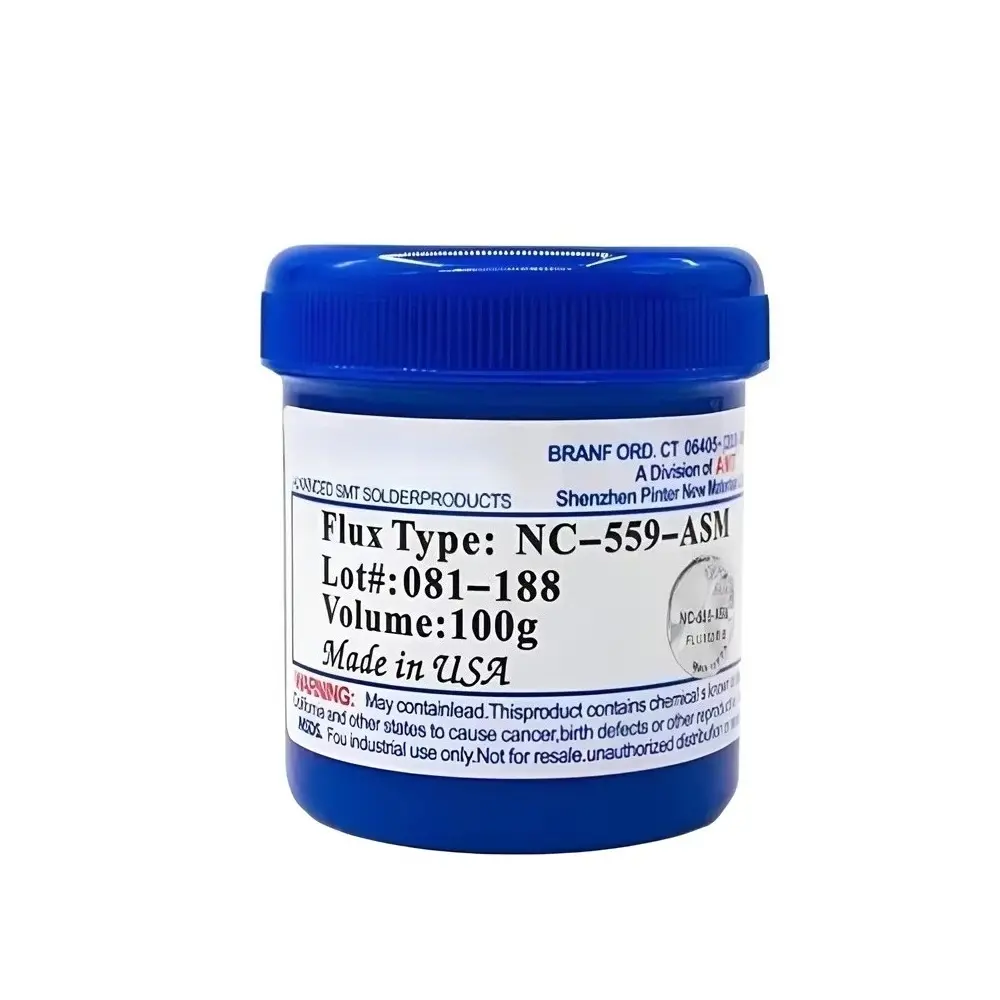

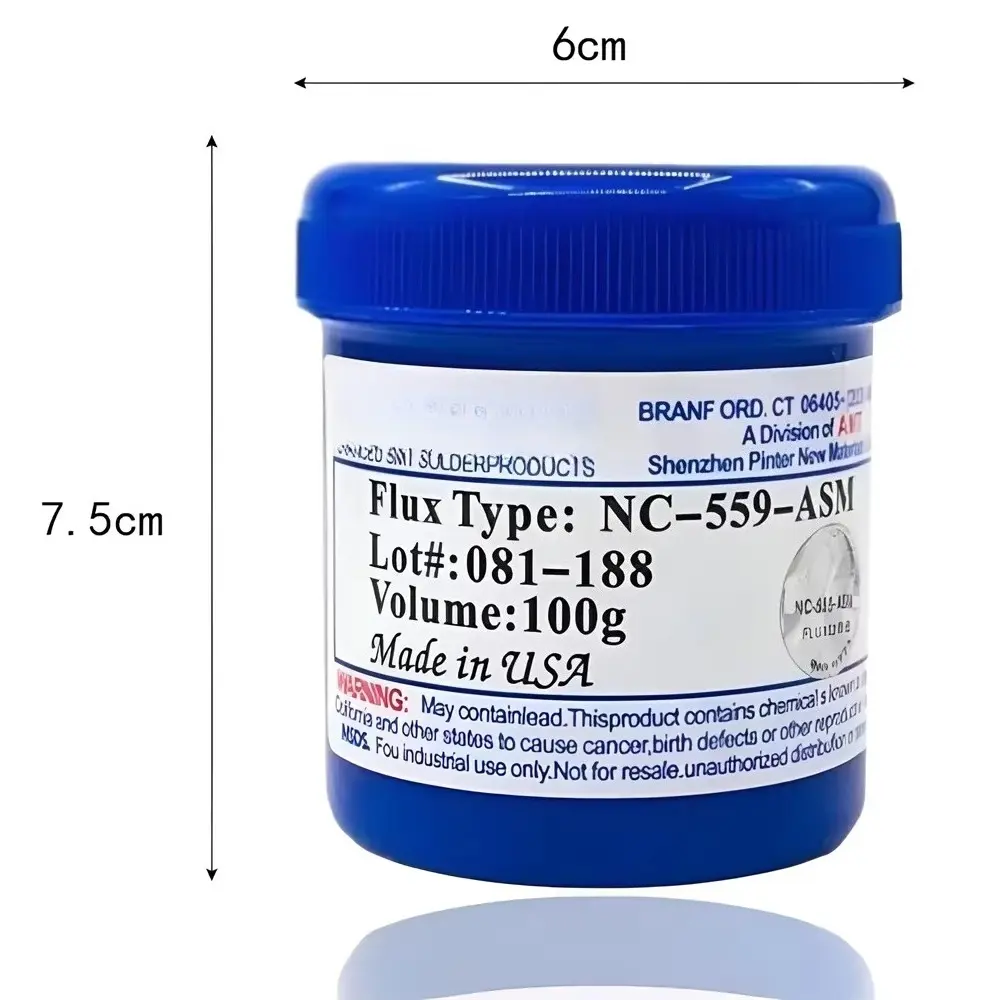

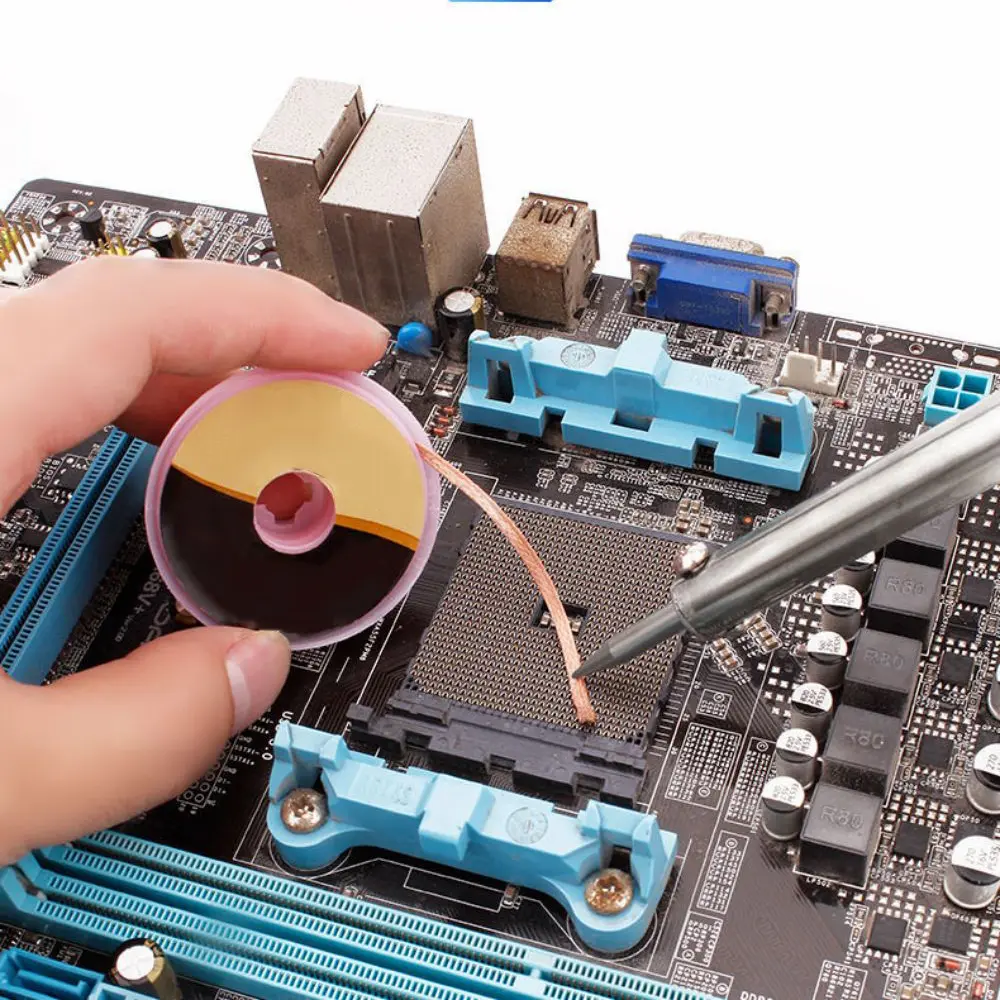

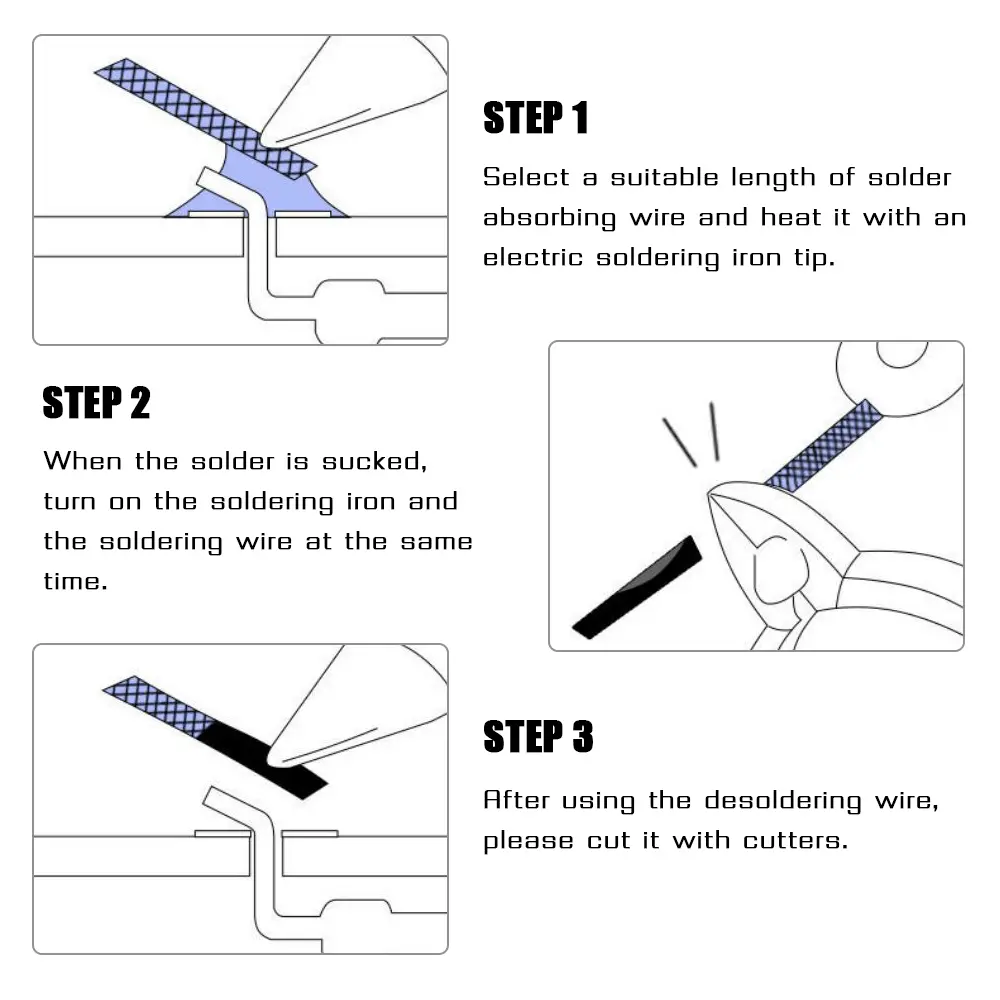

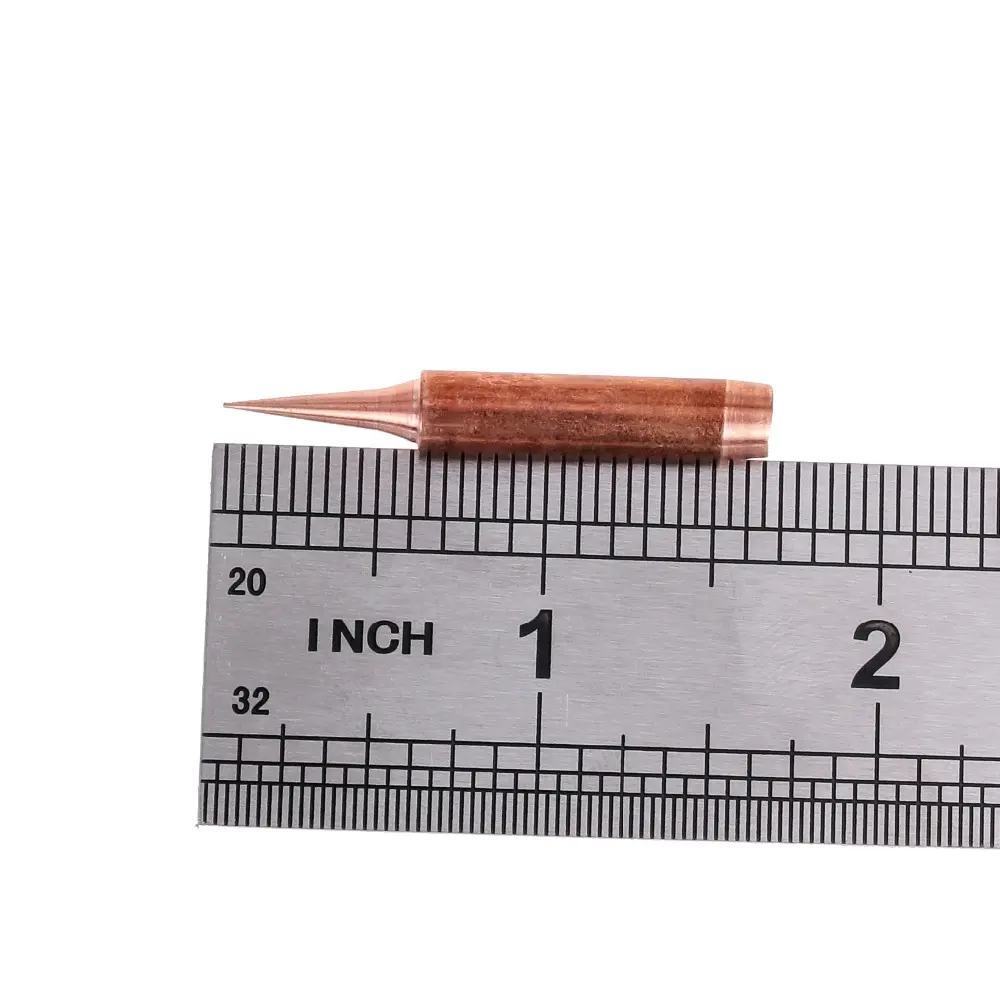

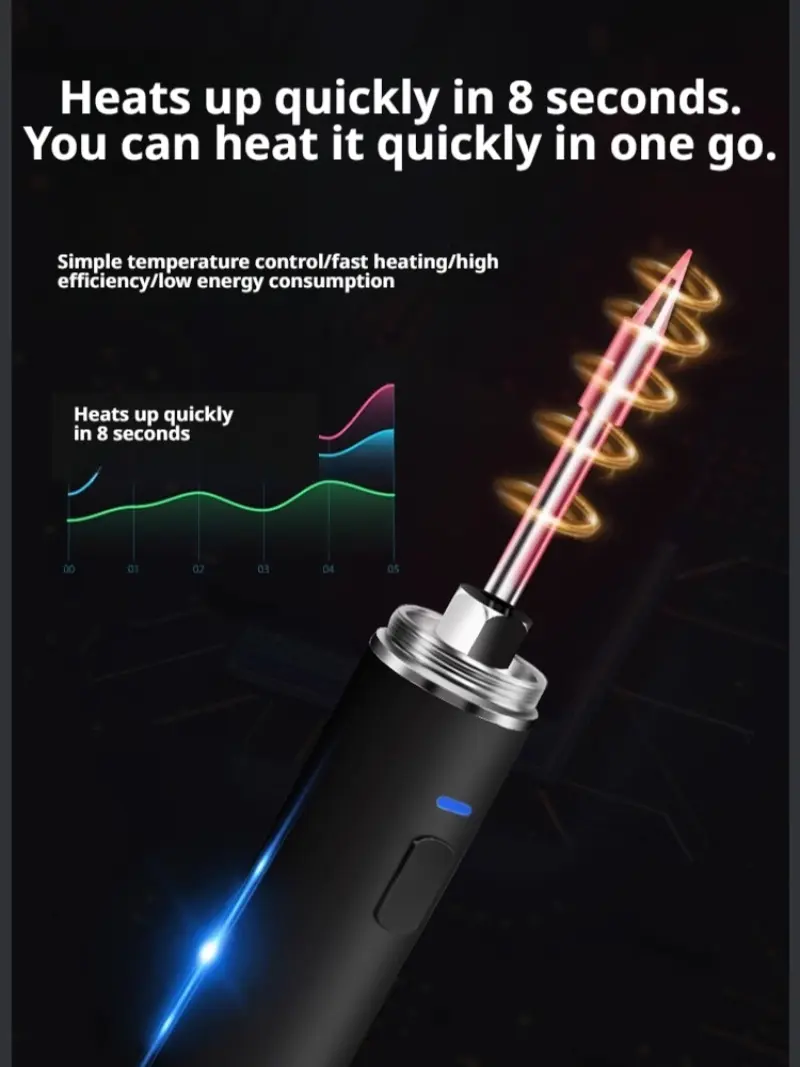

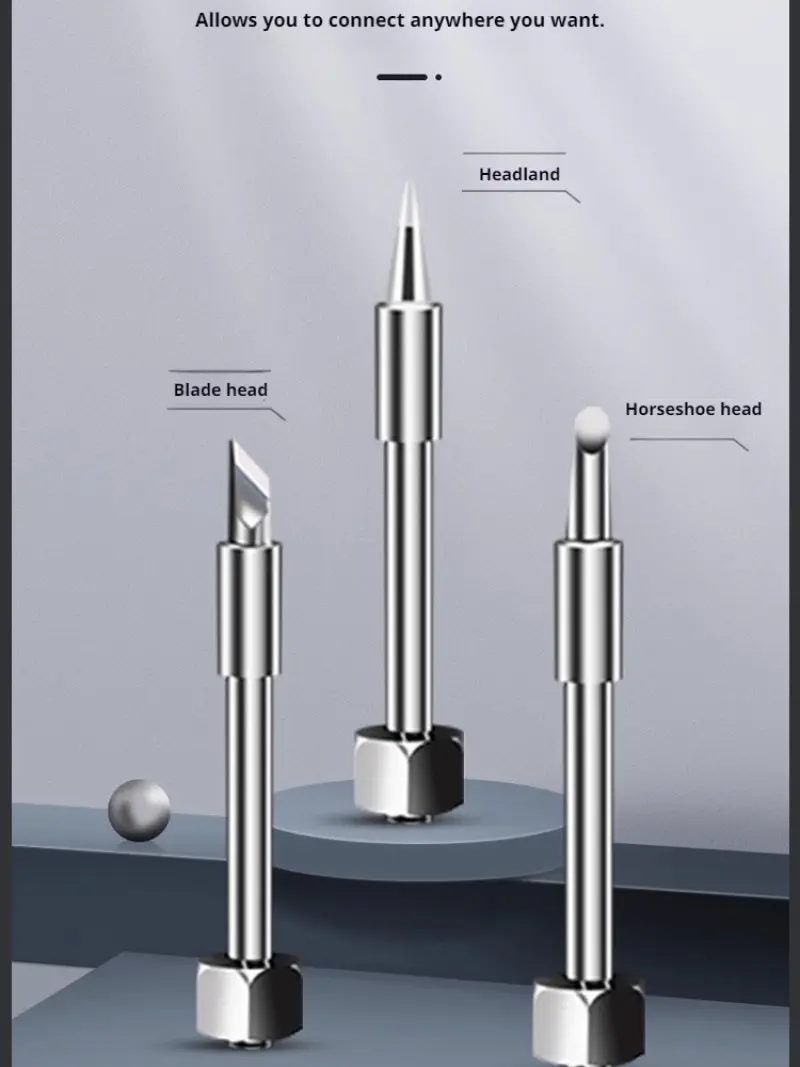

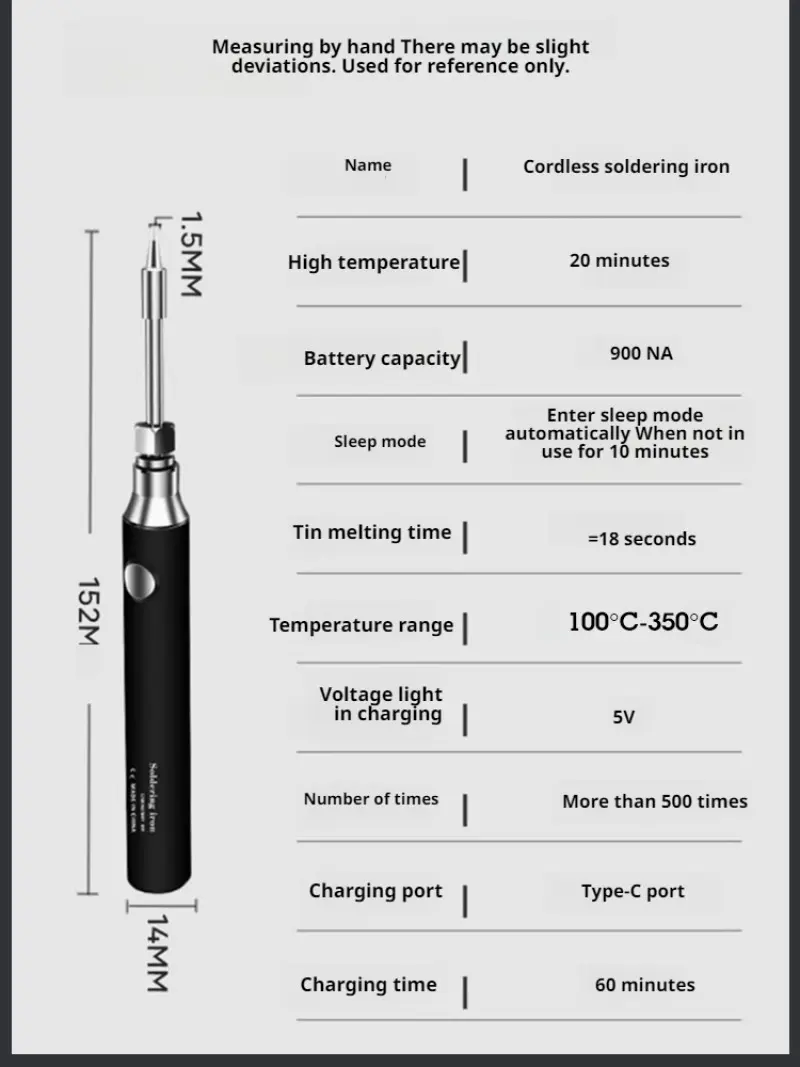

<div class="detailmodule_html"><div class="detail-desc-decorate-richtext"><div><span style="font-size:22px"><span style="background-color:rgb(255, 255, 255);color:rgb(34, 34, 34);font-family:"Open Sans", Roboto, Arial, Helvetica, sans-serif, SimSun"><strong>10ml/Bottle Soldering Flux Liquid Aluminum Metal Electronics Copper Soldering Flux No Water Cleaning 18650 Battery Soldering</strong></span></span><span style="background-color:rgb(255, 255, 255);color:rgb(34, 34, 34);font-size:18px;font-family:"Open Sans", Roboto, Arial, Helvetica, sans-serif, SimSun"><br/>Capacity: 10ml/bottle.</span><br/><span style="background-color:rgb(255, 255, 255);color:rgb(34, 34, 34);font-size:18px;font-family:"Open Sans", Roboto, Arial, Helvetica, sans-serif, SimSun">Size: approx 6x2.1cm/2.4x0.83inches.</span><br/><span style="background-color:rgb(255, 255, 255);color:rgb(34, 34, 34);font-size:18px;font-family:"Open Sans", Roboto, Arial, Helvetica, sans-serif, SimSun">Non-toxic- and environmentally friendly.</span><br/><span style="background-color:rgb(255, 255, 255);color:rgb(34, 34, 34);font-size:18px;font-family:"Open Sans", Roboto, Arial, Helvetica, sans-serif, SimSun">Suitable for pure aluminum sheet, thin aluminum sheet, stainless steel, copper, iron, nickel &alvanized sheet.</span><br/><span style="background-color:rgb(255, 255, 255);color:rgb(34, 34, 34);font-size:18px;font-family:"Open Sans", Roboto, Arial, Helvetica, sans-serif, SimSun">Can not be used for for soldering circuit boards, electronic components.<br/>Welding precautions<br/>1. Ensure that the welding area is dry, clean, free of oil stains and oxidation.<br/>2. Use a high-power soldering iron (welding temperature around 350-400), with optional pointed horseshoe tips for heat transfer and welding (soft pack batteries require soldering iron starting from 200W, large units require soldering iron starting from 500W)<br/>3. Heat the welded area first (the soldering iron head should be tightly attached to the welding area for a few seconds), and quickly feed tin to the welding point at the same time to complete the welding.<br/>4. Attention: During the welding process, the soldering iron should not leave the metal surface. Keep heating and solder the tin wire continuously while it is hot.</span></div><p style="text-align:left;margin:0px;margin-bottom:0px;margin-top:0px;margin-left:0px;margin-right:0px" align="left"></p><p style="margin:0px;margin-bottom:0px;margin-top:0px;margin-left:0px;margin-right:0px;display:block;width:100%"></p></div></div><p><br/></p>

$9.86

$5.615

- Category : Tools

- Brand : stones_store Stone's Store

Colors

Sizes

-

+

<div class="detailmodule_html"><div class="detail-desc-decorate-richtext"><div><span style="font-size:22px"><span style="background-color:rgb(255, 255, 255);color:rgb(34, 34, 34);font-family:"Open Sans", Roboto, Arial, Helvetica, sans-serif, SimSun"><strong>10ml/Bottle Soldering Flux Liquid Aluminum Metal Electronics Copper Soldering Flux No Water Cleaning 18650 Battery Soldering</strong></span></span><span style="background-color:rgb(255, 255, 255);color:rgb(34, 34, 34);font-size:18px;font-family:"Open Sans", Roboto, Arial, Helvetica, sans-serif, SimSun"><br/>Capacity: 10ml/bottle.</span><br/><span style="background-color:rgb(255, 255, 255);color:rgb(34, 34, 34);font-size:18px;font-family:"Open Sans", Roboto, Arial, Helvetica, sans-serif, SimSun">Size: approx 6x2.1cm/2.4x0.83inches.</span><br/><span style="background-color:rgb(255, 255, 255);color:rgb(34, 34, 34);font-size:18px;font-family:"Open Sans", Roboto, Arial, Helvetica, sans-serif, SimSun">Non-toxic- and environmentally friendly.</span><br/><span style="background-color:rgb(255, 255, 255);color:rgb(34, 34, 34);font-size:18px;font-family:"Open Sans", Roboto, Arial, Helvetica, sans-serif, SimSun">Suitable for pure aluminum sheet, thin aluminum sheet, stainless steel, copper, iron, nickel &alvanized sheet.</span><br/><span style="background-color:rgb(255, 255, 255);color:rgb(34, 34, 34);font-size:18px;font-family:"Open Sans", Roboto, Arial, Helvetica, sans-serif, SimSun">Can not be used for for soldering circuit boards, electronic components.<br/>Welding precautions<br/>1. Ensure that the welding area is dry, clean, free of oil stains and oxidation.<br/>2. Use a high-power soldering iron (welding temperature around 350-400), with optional pointed horseshoe tips for heat transfer and welding (soft pack batteries require soldering iron starting from 200W, large units require soldering iron starting from 500W)<br/>3. Heat the welded area first (the soldering iron head should be tightly attached to the welding area for a few seconds), and quickly feed tin to the welding point at the same time to complete the welding.<br/>4. Attention: During the welding process, the soldering iron should not leave the metal surface. Keep heating and solder the tin wire continuously while it is hot.</span></div><p style="text-align:left;margin:0px;margin-bottom:0px;margin-top:0px;margin-left:0px;margin-right:0px" align="left"></p><p style="margin:0px;margin-bottom:0px;margin-top:0px;margin-left:0px;margin-right:0px;display:block;width:100%"></p></div></div><p><br/></p>

Related Product

Browse The Collection of Top Products.