13S 50A/60A Lithium Battery Pack Charge/discharge Protect Board Electric Vehicle Battery Protection Board With Balance BMS

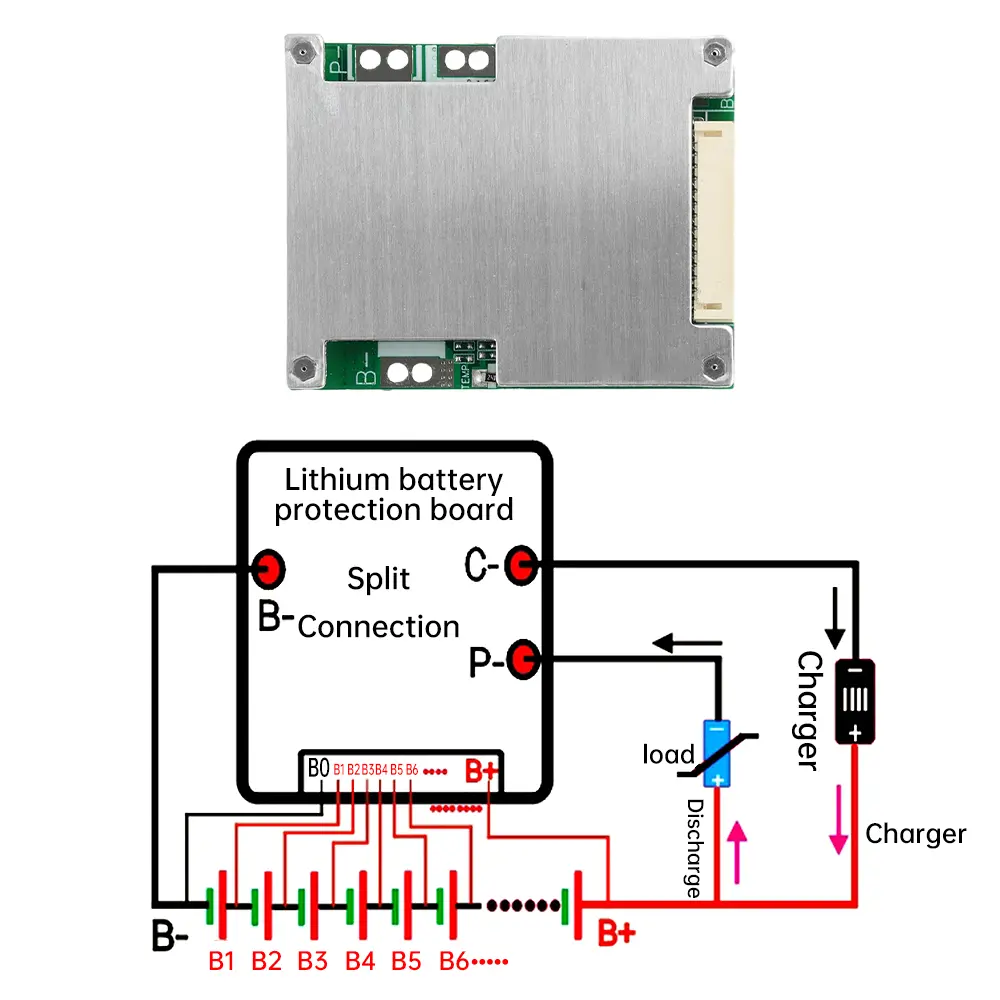

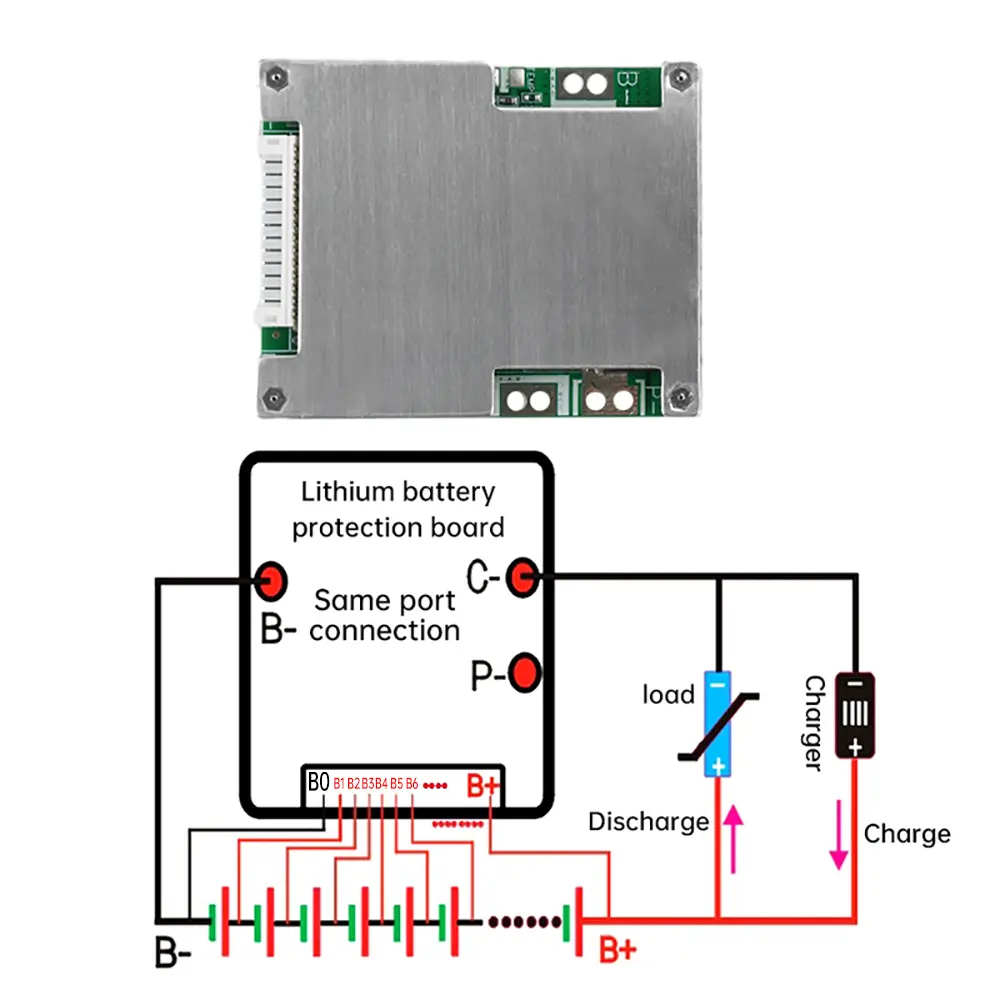

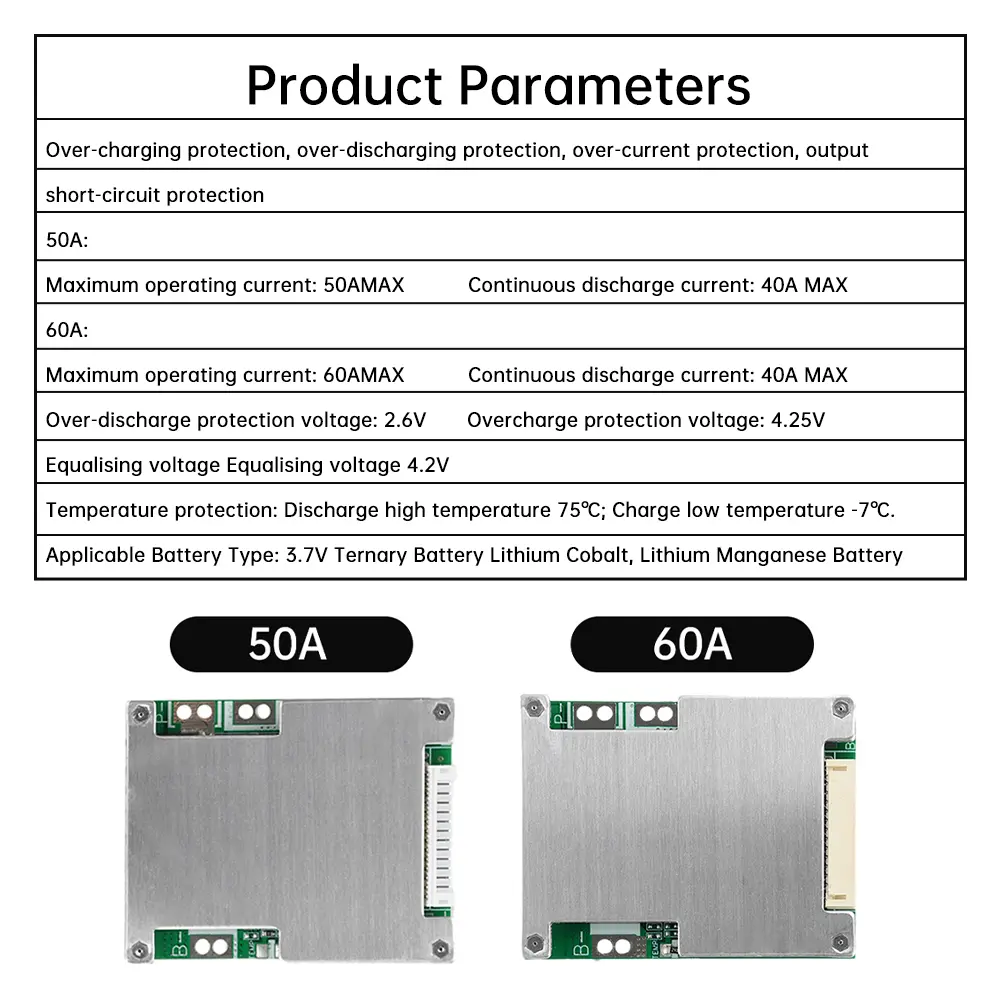

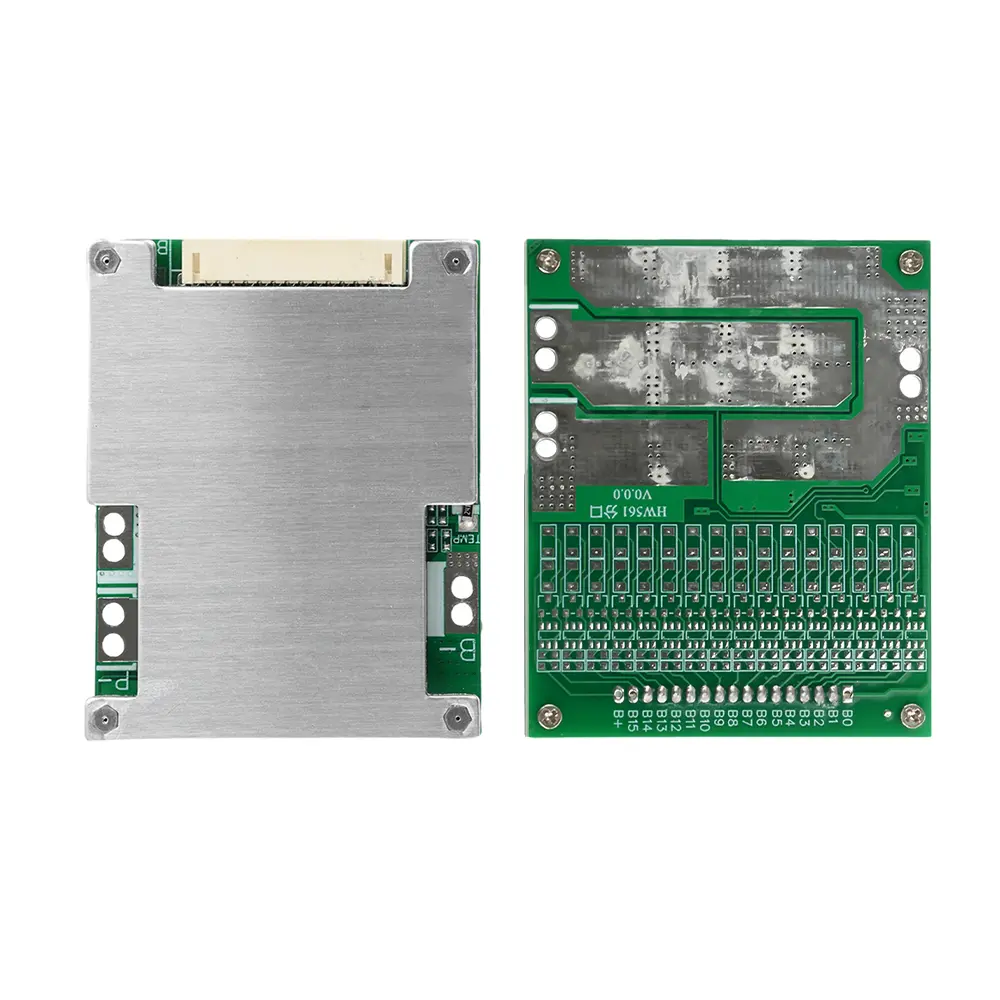

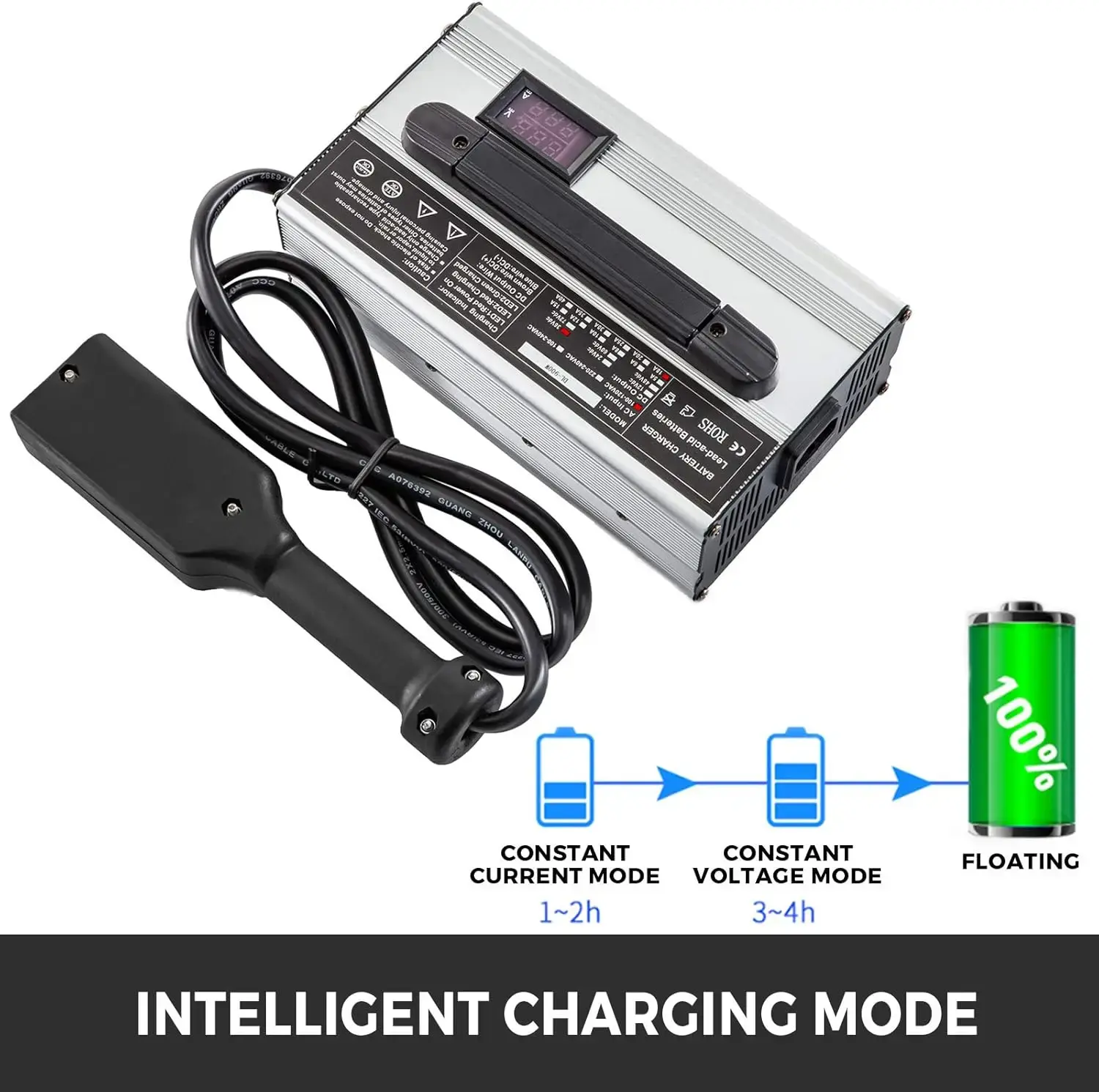

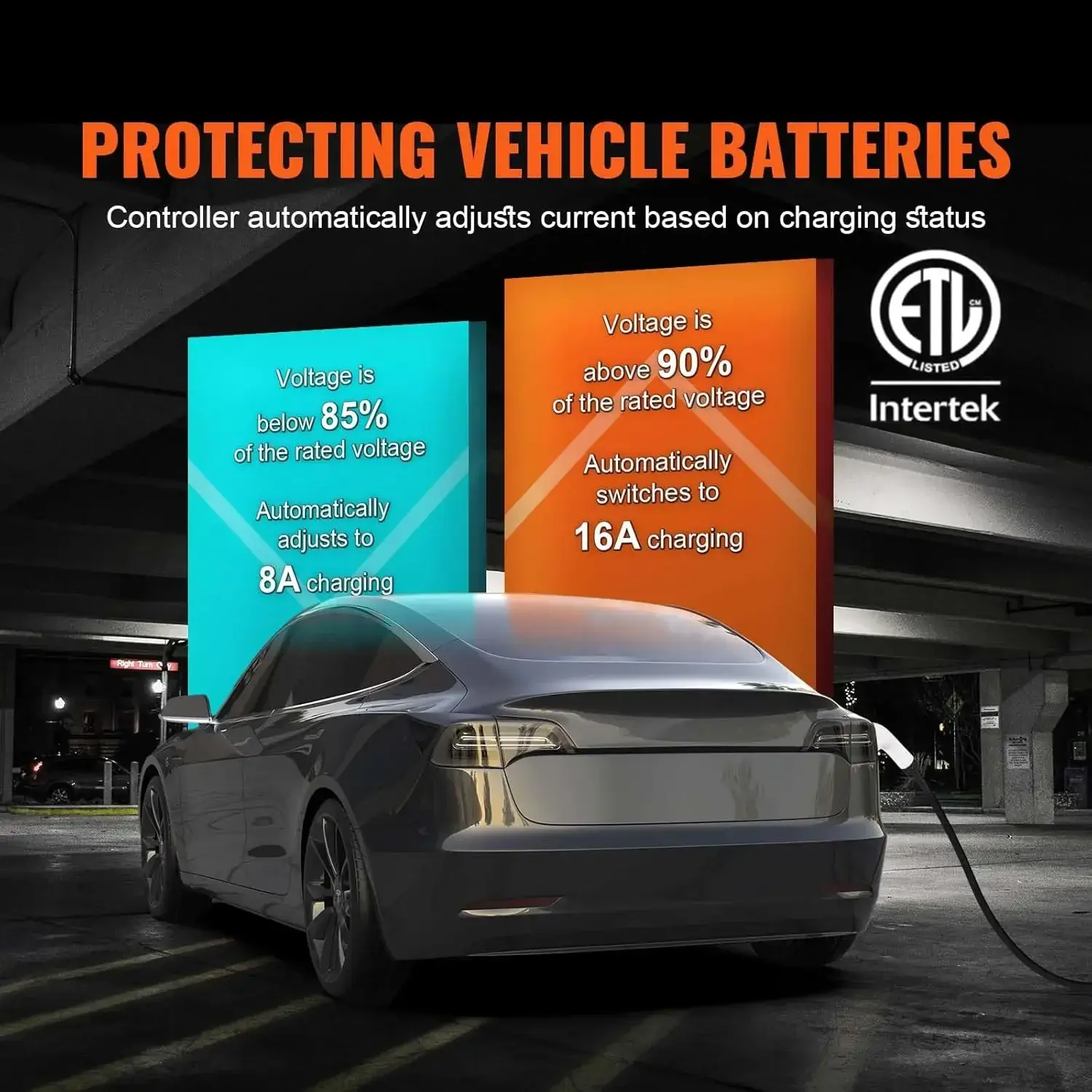

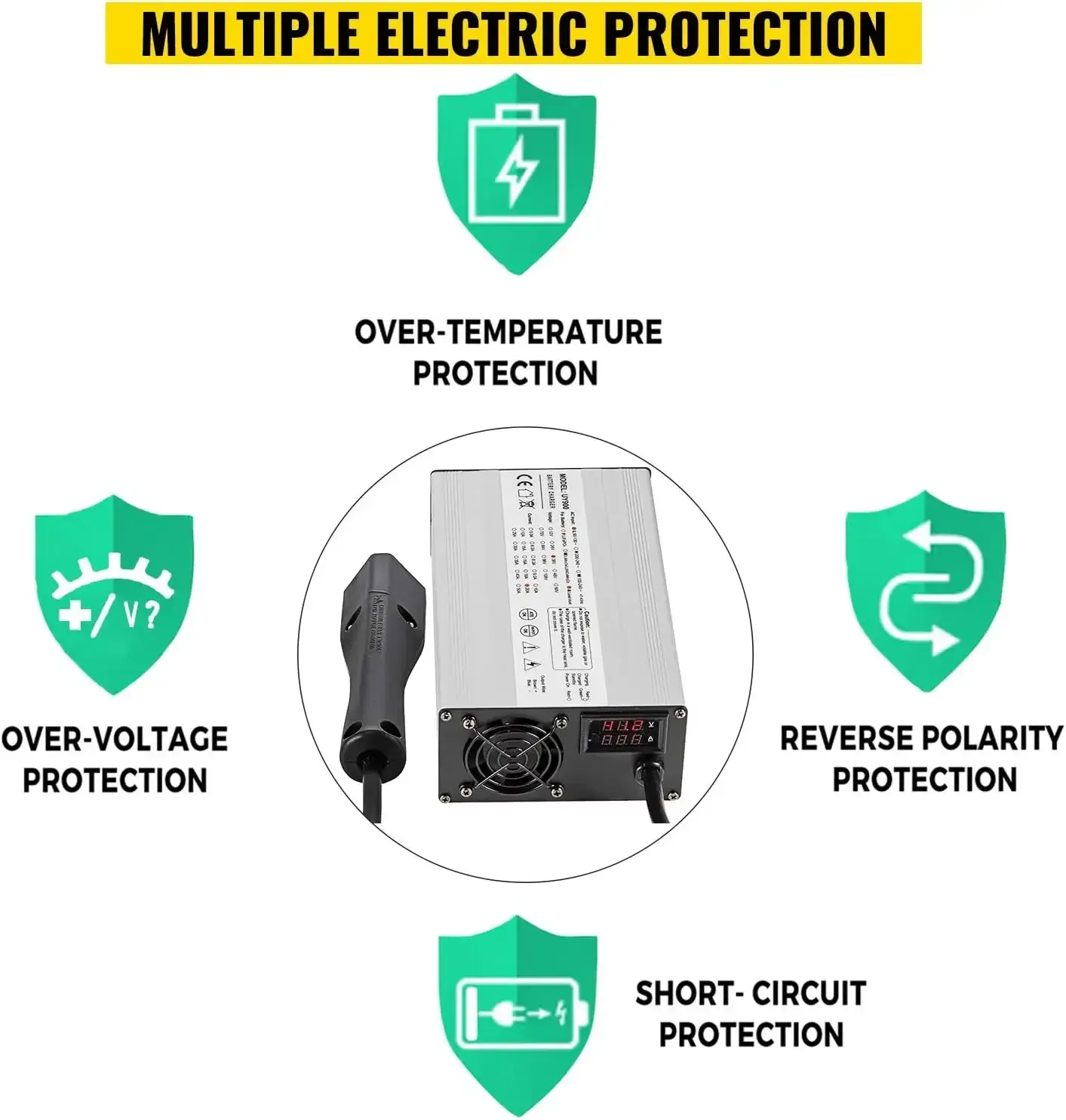

<div class="detailmodule_dynamic"><kse:widget data-widget-type="customText" id="1005000013406005" type="relation"></kse:widget></div><div class="detailmodule_html"><div class="detail-desc-decorate-richtext"><div><br/>Product selling points:<br/>1. Accurately monitor the battery voltage to ensure the safe and stable operation of each battery<br/>2. Support 40A high current continuous output to meet the needs of high-performance electric vehicles<br/>3. Built-in equalization circuit prolongs battery life and improves overall performance<br/>4. Intelligent temperature control system to prevent performance degradation or damage caused by high temperature<br/>5. High quality MOS transistors and capacitors are selected to ensure reliability and long life<br/><br/><br/></div><br/><p>Product parameters:<br/>Over charge protection, over discharge protection, over current protection, output short circuit protection<br/><br/>50A:<br/>Maximum operating current: 50A MAX<br/>Continuous discharge current: 40A MAX<br/><br/>60A:<br/>Maximum operating current: 60A MAX<br/>Continuous discharge current: 40A MAX<br/>Overdischarge protection voltage: 2.6V<br/>Overcharge protection voltage: 4.25V<br/>With balanced charging function, balanced voltage 4.2V<br/>Temperature protection: discharge temperature 75℃; Charging temperature -7℃<br/>Applicable battery type: 3.7V ternary battery lithium cobaltate lithium manganese acid battery</p><p>Wiring steps:<br/>(1) The collection cable is connected to each section of the battery to ensure the effective connection of the cable. Make sure that at the plug end of the cable, the single potential sequence is either increasing or decreasing. The potential sequence is consistent with the potential sequence of the socket at the end of the protection plate and the potential is in one-to-one correspondence.<br/>(2) Weld the B-lead of the protection plate to the total negative B-lead of the battery pack. Ensure that the welding point is firm and reliable and has good conductive characteristics, there is no extrusion, friction and other possible hidden dangers in the line position, and the line is smooth and short. Avoid solder, conductive objects or leads falling into, sticking to or touching the protection plate.<br/>(3) Connect the plug of the cable with the socket of the protection board. First, solder the B-lead of the protection board to the total negative B-lead of the battery pack, and then dock the plug of the cable with the socket of the protection board to ensure that the connection between the plug of the cable and the socket of the protection board is in place, and no live objects or leads touch the protection board, and do a good job in fixing measures.<br/>(4) B+ and C- are connected to the positive and negative electrodes of the charging interface, respectively. Ensure that other leads are isolated during the welding connection process to avoid short circuit. Discharging interface and charging interface test battery pack voltage and battery pack voltage consistency, polarity correctness and wiring position correctness.</p><p>List of parcels:<br/>Lithium battery protection plate *1<br/>Acquisition line *1<br/></p></div></div><br/>

$15.005

$15.005

- Category : Tools

- Brand : z_industry_store Z Industry Store

Colors

Sizes

-

+

<div class="detailmodule_dynamic"><kse:widget data-widget-type="customText" id="1005000013406005" type="relation"></kse:widget></div><div class="detailmodule_html"><div class="detail-desc-decorate-richtext"><div><br/>Product selling points:<br/>1. Accurately monitor the battery voltage to ensure the safe and stable operation of each battery<br/>2. Support 40A high current continuous output to meet the needs of high-performance electric vehicles<br/>3. Built-in equalization circuit prolongs battery life and improves overall performance<br/>4. Intelligent temperature control system to prevent performance degradation or damage caused by high temperature<br/>5. High quality MOS transistors and capacitors are selected to ensure reliability and long life<br/><br/><br/></div><br/><p>Product parameters:<br/>Over charge protection, over discharge protection, over current protection, output short circuit protection<br/><br/>50A:<br/>Maximum operating current: 50A MAX<br/>Continuous discharge current: 40A MAX<br/><br/>60A:<br/>Maximum operating current: 60A MAX<br/>Continuous discharge current: 40A MAX<br/>Overdischarge protection voltage: 2.6V<br/>Overcharge protection voltage: 4.25V<br/>With balanced charging function, balanced voltage 4.2V<br/>Temperature protection: discharge temperature 75℃; Charging temperature -7℃<br/>Applicable battery type: 3.7V ternary battery lithium cobaltate lithium manganese acid battery</p><p>Wiring steps:<br/>(1) The collection cable is connected to each section of the battery to ensure the effective connection of the cable. Make sure that at the plug end of the cable, the single potential sequence is either increasing or decreasing. The potential sequence is consistent with the potential sequence of the socket at the end of the protection plate and the potential is in one-to-one correspondence.<br/>(2) Weld the B-lead of the protection plate to the total negative B-lead of the battery pack. Ensure that the welding point is firm and reliable and has good conductive characteristics, there is no extrusion, friction and other possible hidden dangers in the line position, and the line is smooth and short. Avoid solder, conductive objects or leads falling into, sticking to or touching the protection plate.<br/>(3) Connect the plug of the cable with the socket of the protection board. First, solder the B-lead of the protection board to the total negative B-lead of the battery pack, and then dock the plug of the cable with the socket of the protection board to ensure that the connection between the plug of the cable and the socket of the protection board is in place, and no live objects or leads touch the protection board, and do a good job in fixing measures.<br/>(4) B+ and C- are connected to the positive and negative electrodes of the charging interface, respectively. Ensure that other leads are isolated during the welding connection process to avoid short circuit. Discharging interface and charging interface test battery pack voltage and battery pack voltage consistency, polarity correctness and wiring position correctness.</p><p>List of parcels:<br/>Lithium battery protection plate *1<br/>Acquisition line *1<br/></p></div></div><br/>

Related Product

Browse The Collection of Top Products.