18650 DIY Portable 12V Battery Storage Spot Welding Machine PCB Circuit Board Welding Equipment Spot Welders Pen

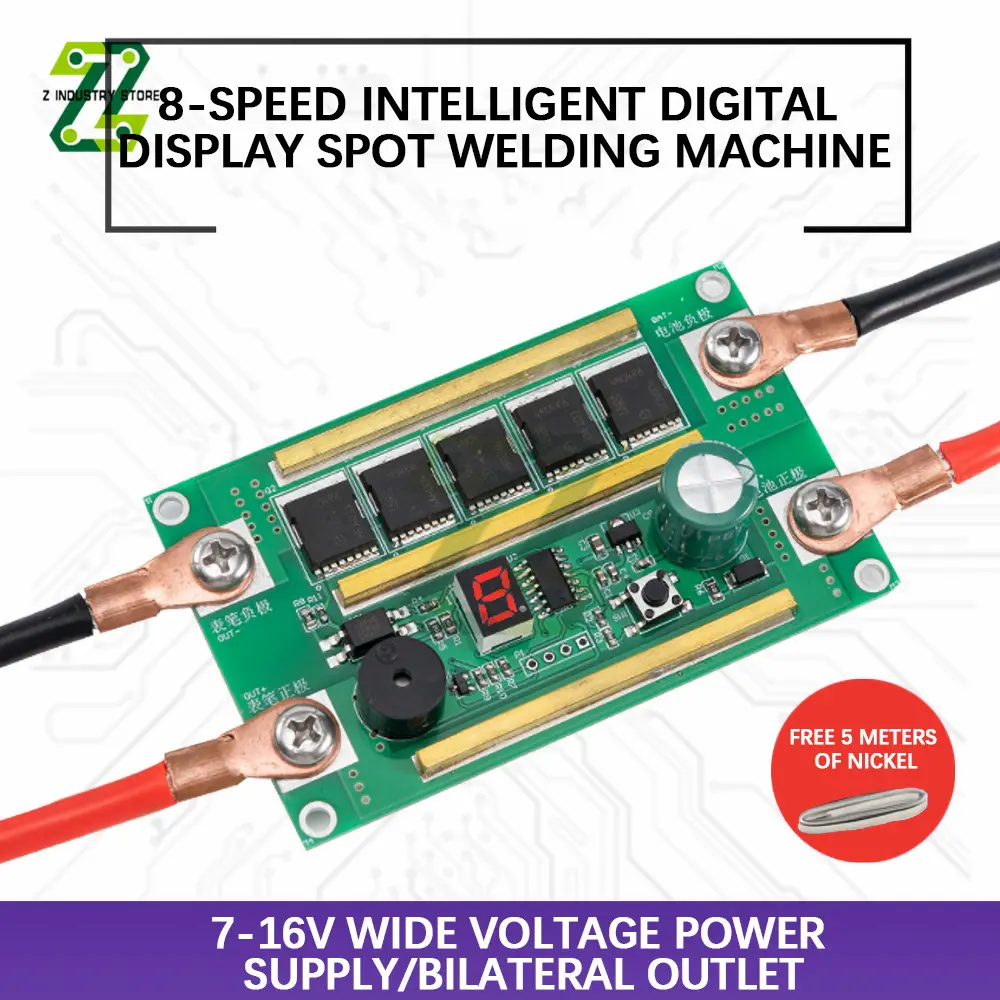

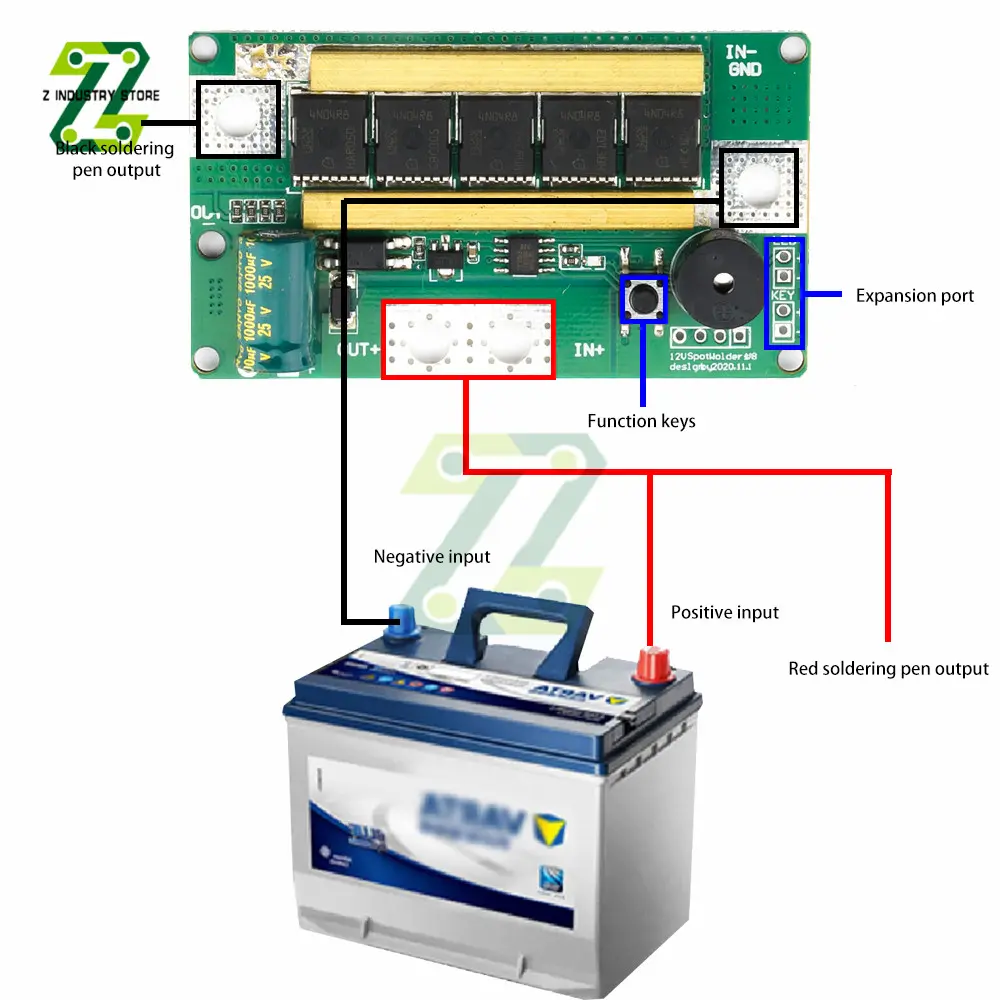

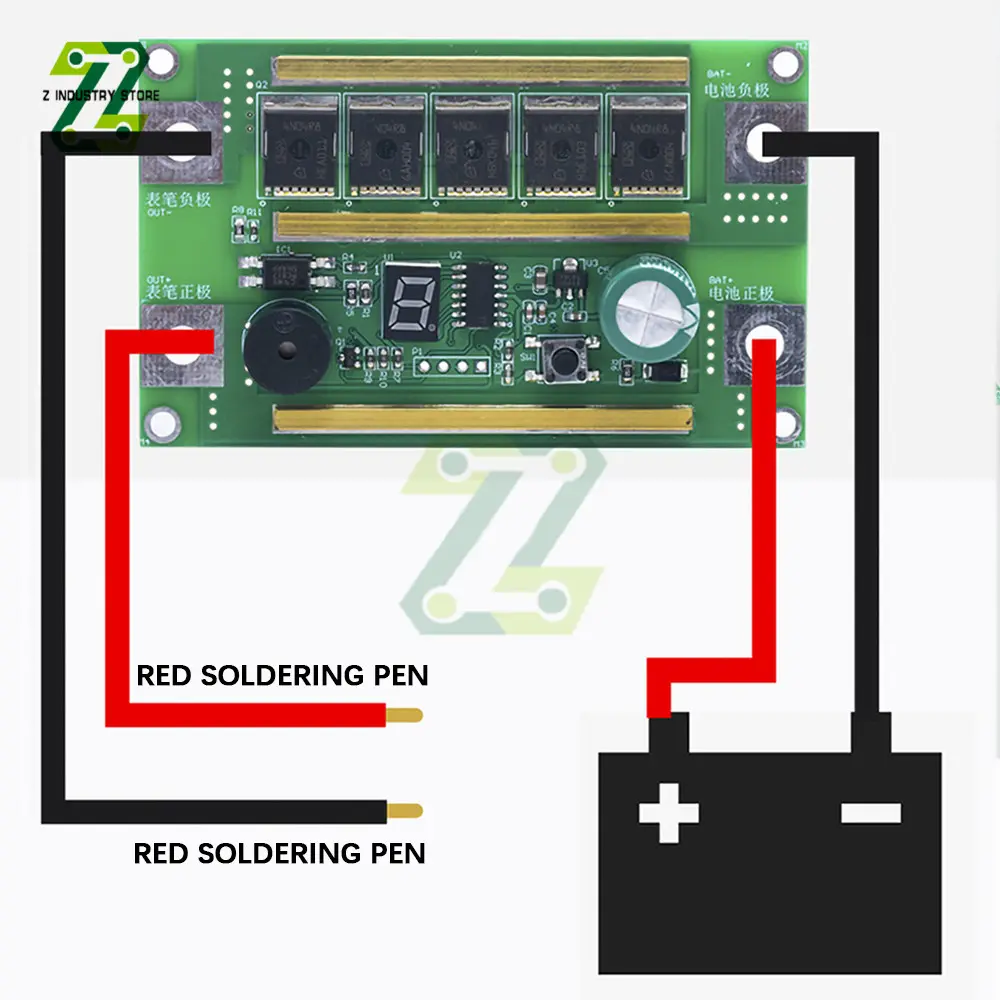

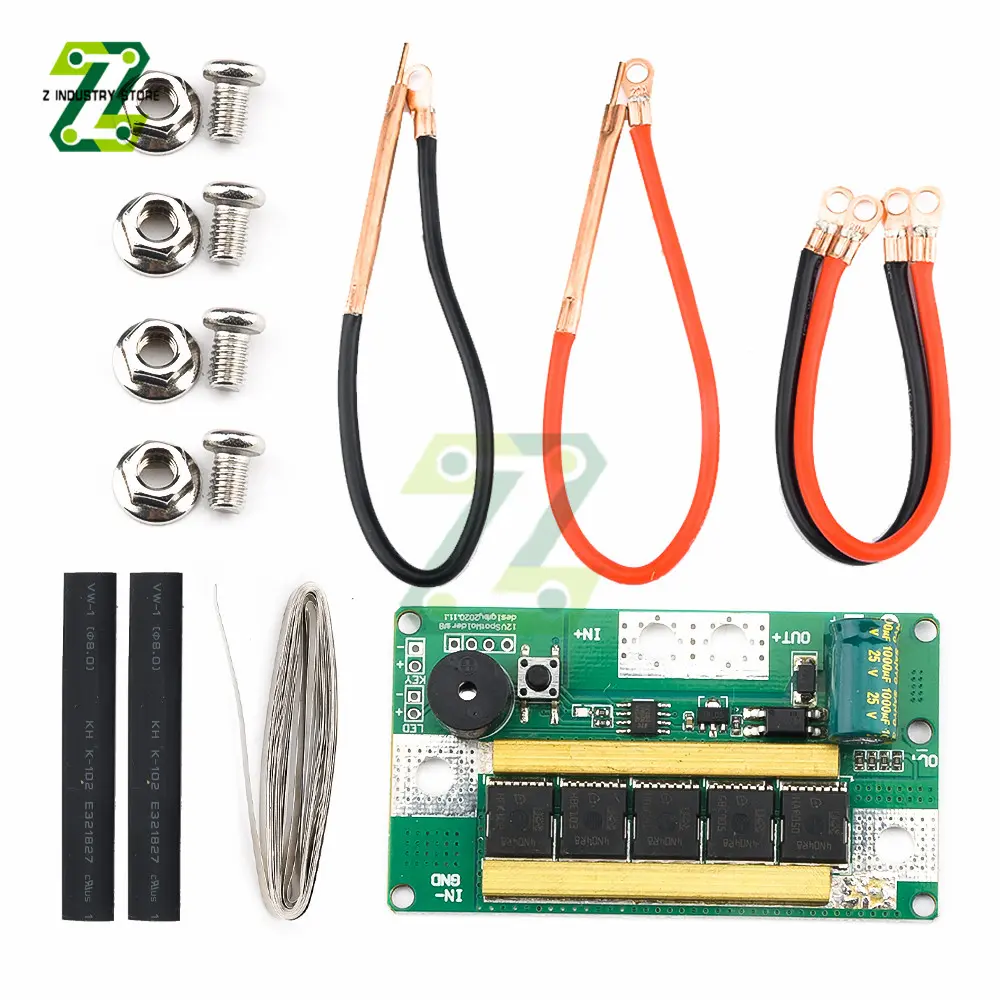

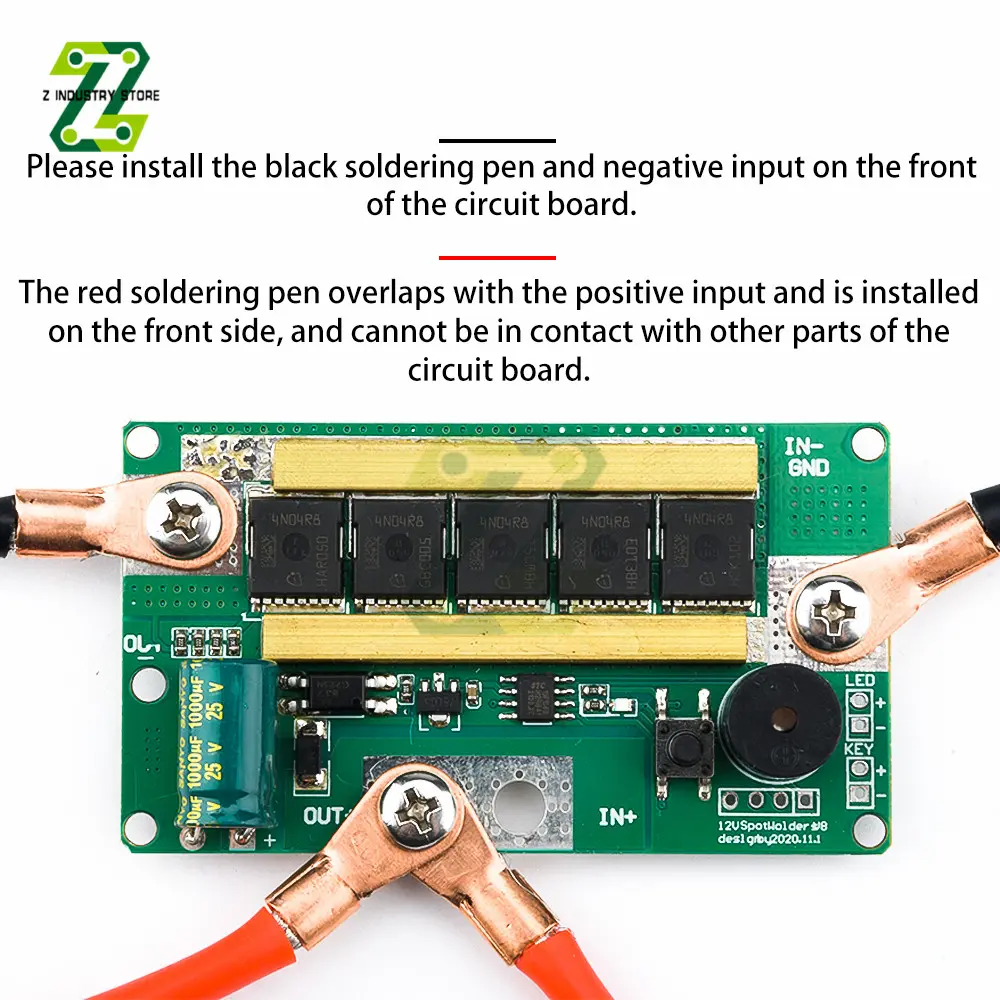

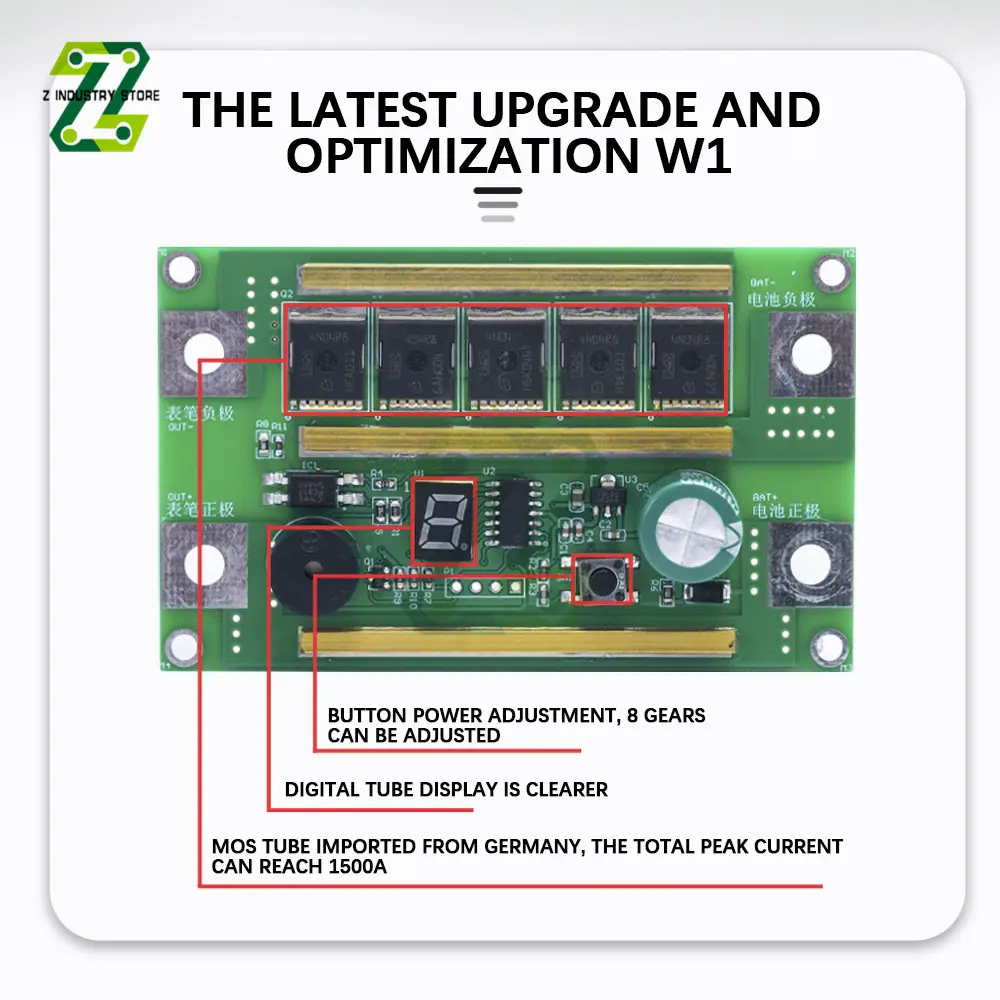

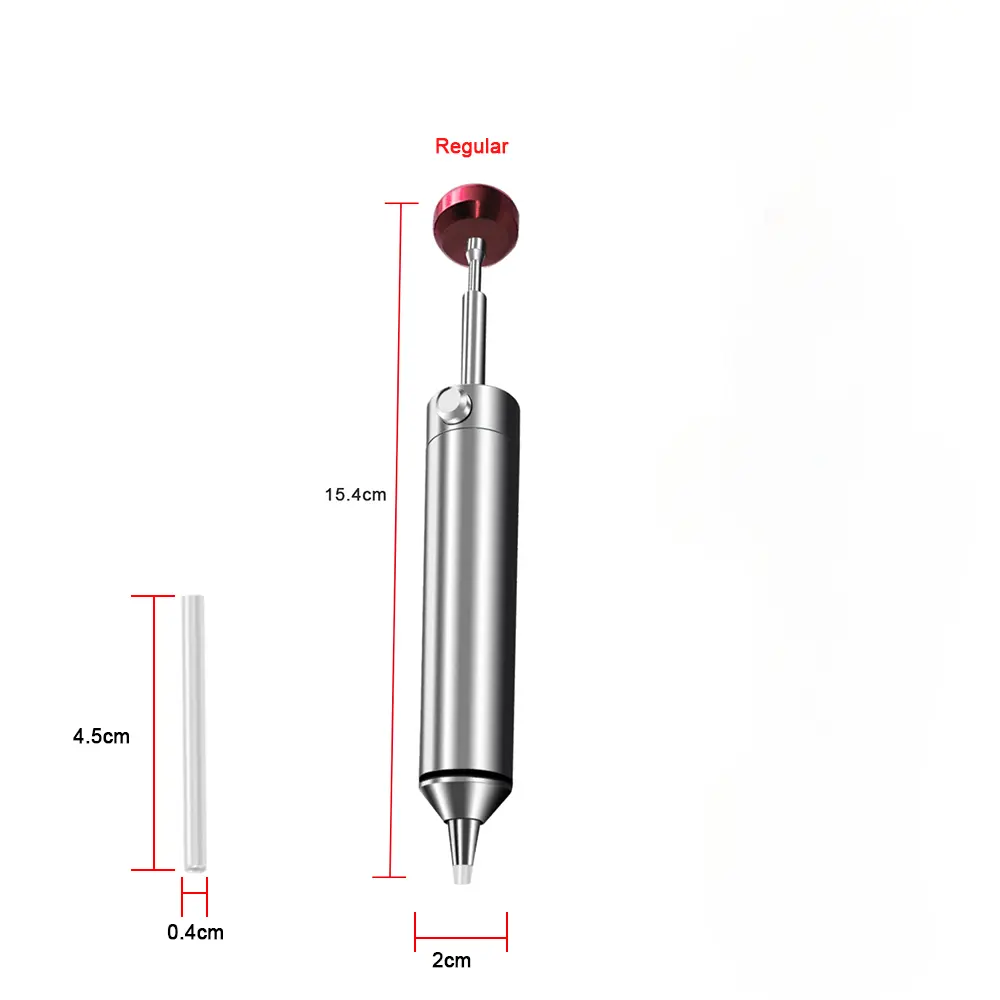

<div class="detailmodule_dynamic"><kse:widget data-widget-type="customText" id="1005000004880420" type="relation"></kse:widget></div><div class="detailmodule_html"><div class="detail-desc-decorate-richtext"><div><br/></div><p><span style="font-size:20px"><strong>18650 DIY Portable 12V Battery Storage Spot Welding Machine PCB Circuit Board Welding Equipment Spot Welders Pen </strong></span></p><p><br/></p><p><span style="color:rgb(244, 78, 59);font-size:20px"><strong>8 gears with display, 5 gears without display</strong></span></p><p><br/></p><p><span style="font-size:20px"><strong>5 gears</strong></span></p><p><br/></p><p><span style="font-size:18px"><strong>The main parameters:</strong></span></p><p><span style="font-size:18px">Power requirements: Spot welding uses the principle of rapid local heating and cooling with high current, and requires sufficient current supply. Generally, the current of 0.1-0.15 nickel-plated sheet welding is about 90-150A, so the working power supply of the circuit board must be greater than or equal to 150A.</span></p><p><br/></p><p><span style="font-size:18px"><strong>Parameter:</strong></span></p><p><span style="font-size:18px">Power supply voltage: 12V-15V</span></p><p><span style="font-size:18px">Working current: 100-200A</span></p><p><span style="font-size:18px">Note: It will not work if it is discharged below 100A.</span></p><p><span style="font-size:18px">A battery with a large discharge current will directly affect the welding effect.</span></p><p><br/></p><p><span style="font-size:18px"><strong>Instructions for use:</strong></span></p><p><span style="font-size:18px">Welding is an engineering discipline. Spot welding is affected by factors such as pulse time, welding angle, strength, and flatness of the welding surface, and the effect will vary.</span></p><p><span style="font-size:18px">When spot welding, just place the soldering pen on the nickel sheet lightly. Do not use force to press the soldering pen. The distance between the two soldering pins is a little closer. If the solder joint becomes black, lower the gear, and if the molten pool is too small, increase the gear.</span></p><p><span style="font-size:18px">Use blades, stainless steel bowls and other iron and stainless steel with larger surfaces before welding, and then weld the battery after familiarizing yourself with the operation.</span></p><p><br/></p><p><span style="font-size:18px"><strong>Instructions for use:</strong></span></p><p><span style="font-size:18px">Welding is an engineering discipline. Spot welding is affected by factors such as pulse time, welding angle and strength, and the flatness of the welding surface. The effect will be different.</span></p><p><span style="font-size:18px">When spot welding, just place the soldering pen on the nickel sheet lightly. Do not use force to press the soldering pen. The welding distance of the two soldering pins is a little closer. If the solder joint is black, lower the gear, and if the molten pool is too small, increase the gear. Before welding, use blades, stainless steel bowls and other iron and stainless steel with large surfaces to try first, and then weld the battery after familiarizing yourself with the operation.</span></p><p><br/></p><p><span style="font-size:18px"><strong>Describe:</strong></span></p><p><span style="font-size:18px">Interface definition: Please strictly follow the instructions for wiring, wrong connection can cause the circuit board to burn out</span></p><p><span style="font-size:18px">Function keys: used to switch the machine and switch gears</span></p><p><span style="font-size:18px">Long press the function button to boot, and default to the first gear, press and hold the function button for 2 seconds to release, the gear will increase by one gear, and the buzzer will sound the number of times the LED flashes corresponding to the gear.</span></p><p><span style="font-size:18px">Example: In gear 3, the buzzer sounds 3 times and the LED flashes 3 times.</span></p><p><span style="font-size:18px">There are 5 gears in total, from the 1st gear to the 5th gear, the spot welding strength is gradually strengthened, and the 5th gear is the strongest. After the 5th gear, press and hold the function key to shut down.</span></p><p><span style="font-size:18px">Note: The buzzer needs to be installed by the user. If it is not installed, it will not affect the welding.</span></p><p><br/></p><p><span style="font-size:18px"><strong>Features:</strong></span></p><p><span style="font-size:18px">1. Portable, stable, reliable and durable. Can be used for welding 18650/26650/32650 and other lithium batteries</span></p><p><span style="font-size:18px">2. The MOS tube driving part is thickened up and down, and copper bars are added to greatly reduce the resistance and increase the overcurrent capability</span></p><p><span style="font-size:18px">3. Add 4 screw holes for easy installation or fixation of the shell</span></p><p><span style="font-size:18px">4. Some circuits have been adjusted to make the layout of the circuit board more reasonable and beautiful</span></p><p><span style="font-size:18px">5. Some circuits have been adjusted to make the circuit board layout more reasonable and beautiful</span></p><p><br/></p><p><span style="font-size:18px"><strong>List:</strong></span></p><p><span style="font-size:18px">Soldering pen*2</span></p><p><span style="font-size:18px">Input wire*2</span></p><p><span style="font-size:18px">Circuit board *1</span></p><p><span style="font-size:18px">Screw set*4</span></p><p><span style="font-size:18px">Heat shrinkable tube*2</span></p><p><span style="font-size:18px">Nickel sheet*1</span></p><p></p><p><br/><br/></p><p><span style="color:rgb(159, 5, 0);font-size:20px"><strong>8 gears</strong></span></p><p><br/></p><p><br/></p><p><strong><span style="font-size:18px">Features</span></strong></p><p><span style="font-size:18px">1: 8-speed intelligent digital display spot welding machine</span></p><p><span style="font-size:18px">2: Super thick copper tube</span></p><p><span style="font-size:18px">3: Pure copper conducts heat conduction, which greatly improves spot welding efficiency</span></p><p><span style="font-size:18px">4: Bilateral outgoing line, easy to spot welding, Chinese label, not easy to connect wrong</span></p><p><span style="font-size:18px">5: Simple to use</span></p><p><br/></p><p><span style="font-size:18px">MOS core operating temperature: 175°C</span></p><p><span style="font-size:18px">Vds: Withstand voltage up to 40V</span></p><p><span style="font-size:18px">Rds(on): The internal resistance of a single chip is as low as 0.77mR</span></p><p><span style="font-size:18px">ld: Single over-current capability 300A</span></p><p><br/></p><p><br/><br/></p><p><strong><span style="font-size:18px">Precautions:</span></strong></p><p><span style="font-size:18px">1. After the system is powered on, the digital tube displays 0, and welding is not possible at this time. You need to adjust the output power (1-8 gears) by pressing the button.</span></p><p><span style="font-size:18px">⒉It is recommended that the power supply voltage is 7V-16V, and the working current is 100-300A. Exceeding this range may damage the control board.</span></p><p><br/></p><p><br/><br/></p><p><strong><span style="font-size:18px">Checklist:</span></strong></p><p><span style="font-size:18px">1*Mini small portable spot welding machine kit</span></p><p></p><p><br/></p><div><br/><br/></div></div></div><p><br/></p>

$20

$20

- Category : Tools

- Brand : z_industry_store Z Industry Store

Colors

Sizes

-

+

<div class="detailmodule_dynamic"><kse:widget data-widget-type="customText" id="1005000004880420" type="relation"></kse:widget></div><div class="detailmodule_html"><div class="detail-desc-decorate-richtext"><div><br/></div><p><span style="font-size:20px"><strong>18650 DIY Portable 12V Battery Storage Spot Welding Machine PCB Circuit Board Welding Equipment Spot Welders Pen </strong></span></p><p><br/></p><p><span style="color:rgb(244, 78, 59);font-size:20px"><strong>8 gears with display, 5 gears without display</strong></span></p><p><br/></p><p><span style="font-size:20px"><strong>5 gears</strong></span></p><p><br/></p><p><span style="font-size:18px"><strong>The main parameters:</strong></span></p><p><span style="font-size:18px">Power requirements: Spot welding uses the principle of rapid local heating and cooling with high current, and requires sufficient current supply. Generally, the current of 0.1-0.15 nickel-plated sheet welding is about 90-150A, so the working power supply of the circuit board must be greater than or equal to 150A.</span></p><p><br/></p><p><span style="font-size:18px"><strong>Parameter:</strong></span></p><p><span style="font-size:18px">Power supply voltage: 12V-15V</span></p><p><span style="font-size:18px">Working current: 100-200A</span></p><p><span style="font-size:18px">Note: It will not work if it is discharged below 100A.</span></p><p><span style="font-size:18px">A battery with a large discharge current will directly affect the welding effect.</span></p><p><br/></p><p><span style="font-size:18px"><strong>Instructions for use:</strong></span></p><p><span style="font-size:18px">Welding is an engineering discipline. Spot welding is affected by factors such as pulse time, welding angle, strength, and flatness of the welding surface, and the effect will vary.</span></p><p><span style="font-size:18px">When spot welding, just place the soldering pen on the nickel sheet lightly. Do not use force to press the soldering pen. The distance between the two soldering pins is a little closer. If the solder joint becomes black, lower the gear, and if the molten pool is too small, increase the gear.</span></p><p><span style="font-size:18px">Use blades, stainless steel bowls and other iron and stainless steel with larger surfaces before welding, and then weld the battery after familiarizing yourself with the operation.</span></p><p><br/></p><p><span style="font-size:18px"><strong>Instructions for use:</strong></span></p><p><span style="font-size:18px">Welding is an engineering discipline. Spot welding is affected by factors such as pulse time, welding angle and strength, and the flatness of the welding surface. The effect will be different.</span></p><p><span style="font-size:18px">When spot welding, just place the soldering pen on the nickel sheet lightly. Do not use force to press the soldering pen. The welding distance of the two soldering pins is a little closer. If the solder joint is black, lower the gear, and if the molten pool is too small, increase the gear. Before welding, use blades, stainless steel bowls and other iron and stainless steel with large surfaces to try first, and then weld the battery after familiarizing yourself with the operation.</span></p><p><br/></p><p><span style="font-size:18px"><strong>Describe:</strong></span></p><p><span style="font-size:18px">Interface definition: Please strictly follow the instructions for wiring, wrong connection can cause the circuit board to burn out</span></p><p><span style="font-size:18px">Function keys: used to switch the machine and switch gears</span></p><p><span style="font-size:18px">Long press the function button to boot, and default to the first gear, press and hold the function button for 2 seconds to release, the gear will increase by one gear, and the buzzer will sound the number of times the LED flashes corresponding to the gear.</span></p><p><span style="font-size:18px">Example: In gear 3, the buzzer sounds 3 times and the LED flashes 3 times.</span></p><p><span style="font-size:18px">There are 5 gears in total, from the 1st gear to the 5th gear, the spot welding strength is gradually strengthened, and the 5th gear is the strongest. After the 5th gear, press and hold the function key to shut down.</span></p><p><span style="font-size:18px">Note: The buzzer needs to be installed by the user. If it is not installed, it will not affect the welding.</span></p><p><br/></p><p><span style="font-size:18px"><strong>Features:</strong></span></p><p><span style="font-size:18px">1. Portable, stable, reliable and durable. Can be used for welding 18650/26650/32650 and other lithium batteries</span></p><p><span style="font-size:18px">2. The MOS tube driving part is thickened up and down, and copper bars are added to greatly reduce the resistance and increase the overcurrent capability</span></p><p><span style="font-size:18px">3. Add 4 screw holes for easy installation or fixation of the shell</span></p><p><span style="font-size:18px">4. Some circuits have been adjusted to make the layout of the circuit board more reasonable and beautiful</span></p><p><span style="font-size:18px">5. Some circuits have been adjusted to make the circuit board layout more reasonable and beautiful</span></p><p><br/></p><p><span style="font-size:18px"><strong>List:</strong></span></p><p><span style="font-size:18px">Soldering pen*2</span></p><p><span style="font-size:18px">Input wire*2</span></p><p><span style="font-size:18px">Circuit board *1</span></p><p><span style="font-size:18px">Screw set*4</span></p><p><span style="font-size:18px">Heat shrinkable tube*2</span></p><p><span style="font-size:18px">Nickel sheet*1</span></p><p></p><p><br/><br/></p><p><span style="color:rgb(159, 5, 0);font-size:20px"><strong>8 gears</strong></span></p><p><br/></p><p><br/></p><p><strong><span style="font-size:18px">Features</span></strong></p><p><span style="font-size:18px">1: 8-speed intelligent digital display spot welding machine</span></p><p><span style="font-size:18px">2: Super thick copper tube</span></p><p><span style="font-size:18px">3: Pure copper conducts heat conduction, which greatly improves spot welding efficiency</span></p><p><span style="font-size:18px">4: Bilateral outgoing line, easy to spot welding, Chinese label, not easy to connect wrong</span></p><p><span style="font-size:18px">5: Simple to use</span></p><p><br/></p><p><span style="font-size:18px">MOS core operating temperature: 175°C</span></p><p><span style="font-size:18px">Vds: Withstand voltage up to 40V</span></p><p><span style="font-size:18px">Rds(on): The internal resistance of a single chip is as low as 0.77mR</span></p><p><span style="font-size:18px">ld: Single over-current capability 300A</span></p><p><br/></p><p><br/><br/></p><p><strong><span style="font-size:18px">Precautions:</span></strong></p><p><span style="font-size:18px">1. After the system is powered on, the digital tube displays 0, and welding is not possible at this time. You need to adjust the output power (1-8 gears) by pressing the button.</span></p><p><span style="font-size:18px">⒉It is recommended that the power supply voltage is 7V-16V, and the working current is 100-300A. Exceeding this range may damage the control board.</span></p><p><br/></p><p><br/><br/></p><p><strong><span style="font-size:18px">Checklist:</span></strong></p><p><span style="font-size:18px">1*Mini small portable spot welding machine kit</span></p><p></p><p><br/></p><div><br/><br/></div></div></div><p><br/></p>

Related Product

Browse The Collection of Top Products.