1pc JS30 Micro Gear Motor DC 6V Plastic Gear Electric Motor 5RPM 100RPM Φ5mm D Shaft Reversible for Automation Equipment

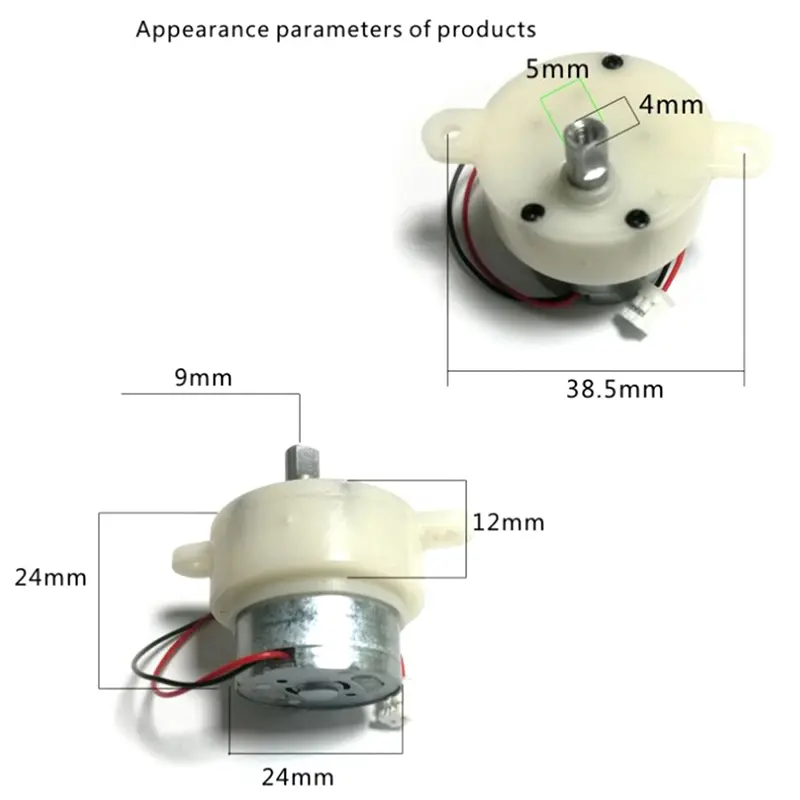

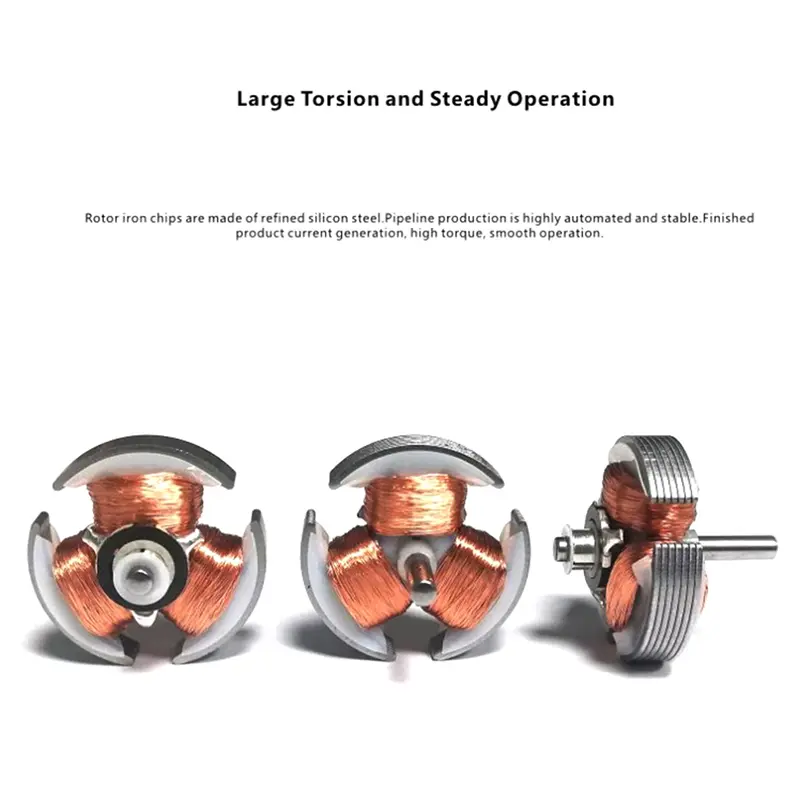

<div class="detailmodule_html"><div class="detail-desc-decorate-richtext"><p><span style="font-size:16px;font-family:Verdana;">JS30 Micro Gear Motor DC 6V Plastic Gear Electric Motor 5RPM 100RPM Φ5mm D Shaft Reversible for Automation Equipment</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">● Product Properties :</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">Motor Model : JS-30</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">Power Supply : DC 6V</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">Shaft Diameter : 5mm</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">Speed : 5RPM , 100RPM</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">● Motor characteristics :</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">The plastic gear material is used, which is light in weight, low working noise, wear-resistant, and does not require lubrication. The rotation of the motor can be changed by changing the positive and negative terminals of the terminal wiring. The double flat holes are more convenient to install, not easy to slip, and save installation time.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">● Motor use :</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">JS-30 DC gear motor is suitable for all kinds of display stands, handicrafts, rotating lighting lamps, electric toys, small magic balls, etc. with a wide range of applications. Using DC power supply, the available voltage is DC1.5V-12V, and the speed can be 2-200R/ Min selection.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">● Motor Considerations :</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">1. When you use the motor, there should be no binding objects. For example, the adhesive should not flow into the bearing through the rotating shaft, which will hinder the operation of the motor.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">2. The rotation of the shaft may have the opposite effect on the life of the motor. In order to prolong the life, please check whether your load is in accordance with the regulations. Do not overload or have objects that hinder rotation at the end of the shaft.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">3. Manufactured into an eccentric heavy radiation load, which is harmful to the life of the motor.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">4. Do not store in surrounding high temperature or extreme humidity, and do not place in corrosive gas, which will reduce the effect of the motor.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">5. Do not run the motor in the surrounding high temperature and humidity.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">6. When soldering is required on the positive and negative motor terminals of the power supply, the temperature of the soldering iron is 340C±40C, and the heating time is within 3 seconds. Do not deform the plastic. Let the solder points flow into the motor or break the end of the wire during work, which will make the motor Functional decline.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">7. Don't let the motor shaft get stuck. When power is supplied, the motor will overheat in a short time and its accessories will be burnt.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">8. Due to the lack of skills of the staff, the quality of the motor cannot be guaranteed when the motor encounters the things mentioned in the manual, or the superficial judgment is obviously fault.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">9. Supply the specified power and be sure that it is within the range of measurable requirements.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">10. The installation of pulleys or gears should not be abnormally aggravated when they are pressed in.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">11. When installing the motor, if the screw is too long, it will cause contact between the motor itself and the rotor, which will affect the characteristics.</span></p></div></div>

<div class="detailmodule_image"></div>

$9.515

$5.615

- Category : Home Improvement

- Brand : ali_tg16_store Ali-TG16 Store

Colors

Sizes

-

+

<div class="detailmodule_html"><div class="detail-desc-decorate-richtext"><p><span style="font-size:16px;font-family:Verdana;">JS30 Micro Gear Motor DC 6V Plastic Gear Electric Motor 5RPM 100RPM Φ5mm D Shaft Reversible for Automation Equipment</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">● Product Properties :</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">Motor Model : JS-30</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">Power Supply : DC 6V</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">Shaft Diameter : 5mm</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">Speed : 5RPM , 100RPM</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">● Motor characteristics :</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">The plastic gear material is used, which is light in weight, low working noise, wear-resistant, and does not require lubrication. The rotation of the motor can be changed by changing the positive and negative terminals of the terminal wiring. The double flat holes are more convenient to install, not easy to slip, and save installation time.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">● Motor use :</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">JS-30 DC gear motor is suitable for all kinds of display stands, handicrafts, rotating lighting lamps, electric toys, small magic balls, etc. with a wide range of applications. Using DC power supply, the available voltage is DC1.5V-12V, and the speed can be 2-200R/ Min selection.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">● Motor Considerations :</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">1. When you use the motor, there should be no binding objects. For example, the adhesive should not flow into the bearing through the rotating shaft, which will hinder the operation of the motor.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">2. The rotation of the shaft may have the opposite effect on the life of the motor. In order to prolong the life, please check whether your load is in accordance with the regulations. Do not overload or have objects that hinder rotation at the end of the shaft.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">3. Manufactured into an eccentric heavy radiation load, which is harmful to the life of the motor.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">4. Do not store in surrounding high temperature or extreme humidity, and do not place in corrosive gas, which will reduce the effect of the motor.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">5. Do not run the motor in the surrounding high temperature and humidity.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">6. When soldering is required on the positive and negative motor terminals of the power supply, the temperature of the soldering iron is 340C±40C, and the heating time is within 3 seconds. Do not deform the plastic. Let the solder points flow into the motor or break the end of the wire during work, which will make the motor Functional decline.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">7. Don't let the motor shaft get stuck. When power is supplied, the motor will overheat in a short time and its accessories will be burnt.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">8. Due to the lack of skills of the staff, the quality of the motor cannot be guaranteed when the motor encounters the things mentioned in the manual, or the superficial judgment is obviously fault.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">9. Supply the specified power and be sure that it is within the range of measurable requirements.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">10. The installation of pulleys or gears should not be abnormally aggravated when they are pressed in.</span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;"><br></span></p><p><span style="font-size:16px;font-family:Verdana;">11. When installing the motor, if the screw is too long, it will cause contact between the motor itself and the rotor, which will affect the characteristics.</span></p></div></div>

<div class="detailmodule_image"></div>