Electric Vacuum Solder Sucker Welding Desoldering Pump Soldering Iron Removal Solder Iron Pen Welding Repair Tool

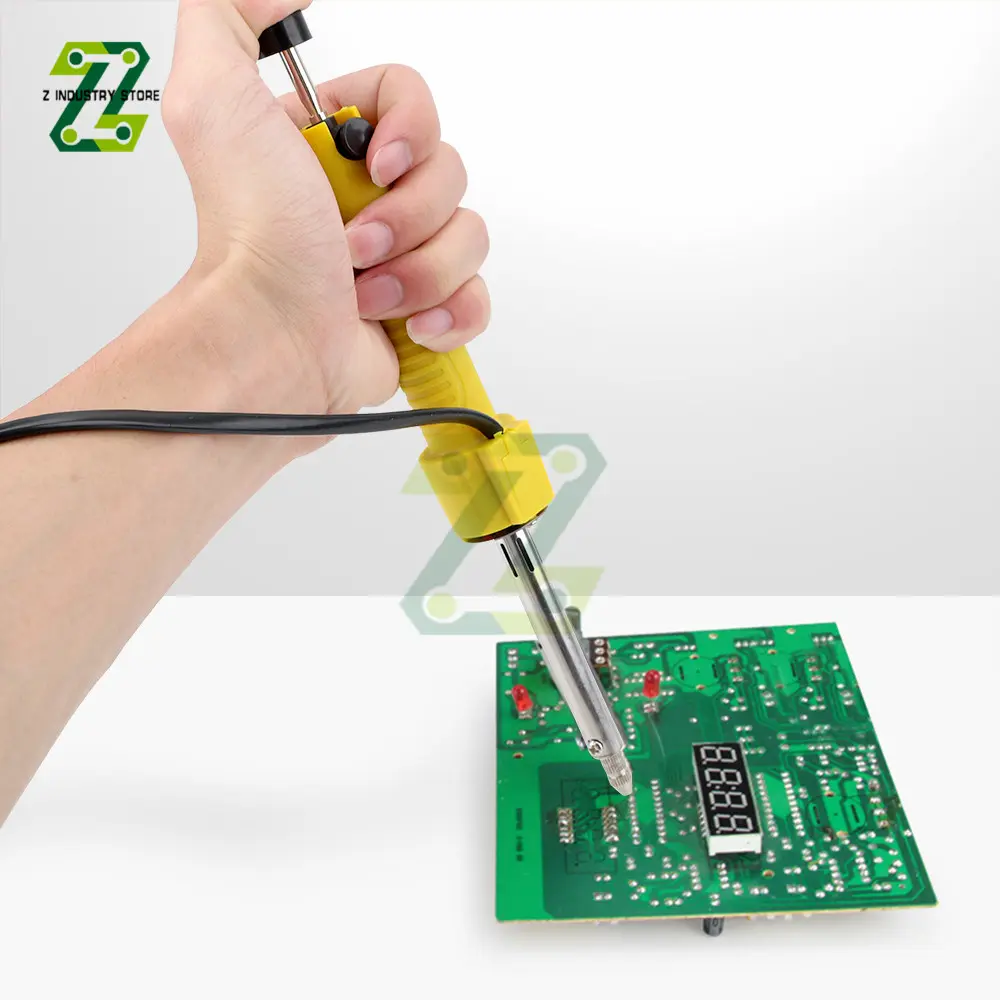

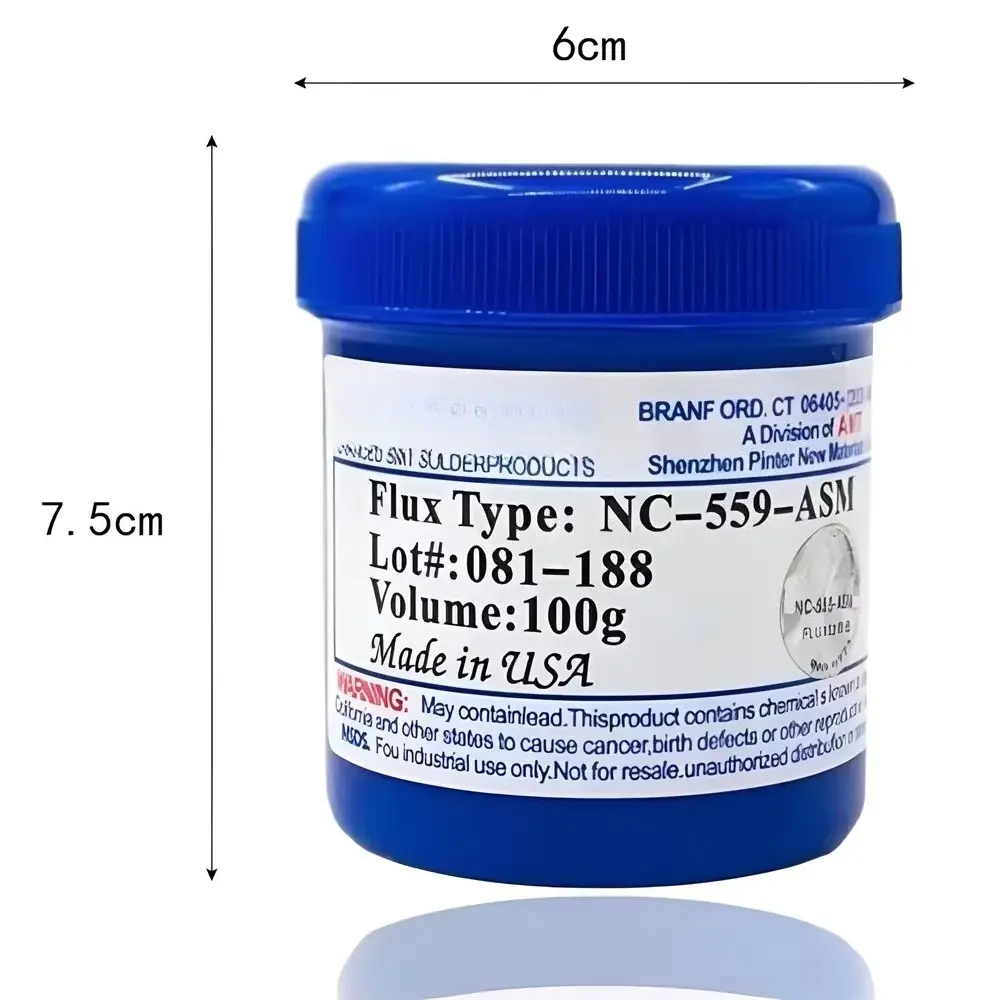

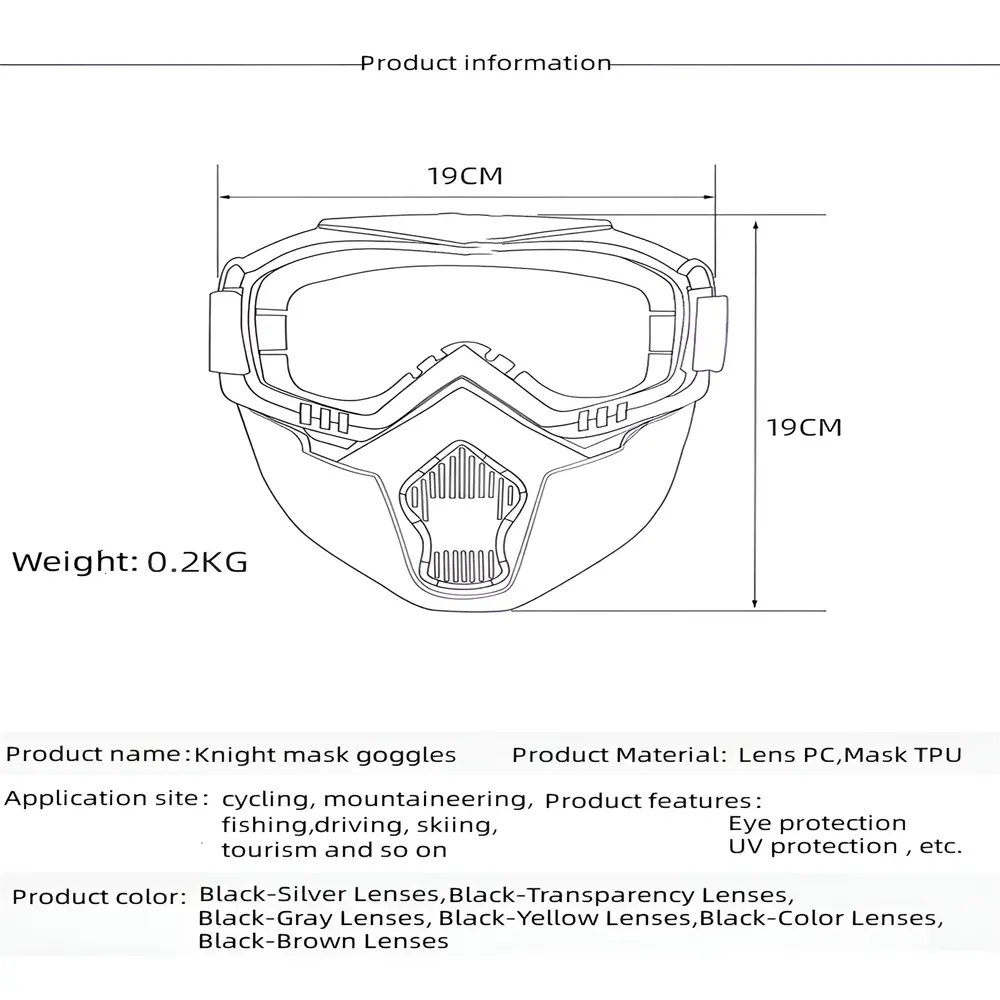

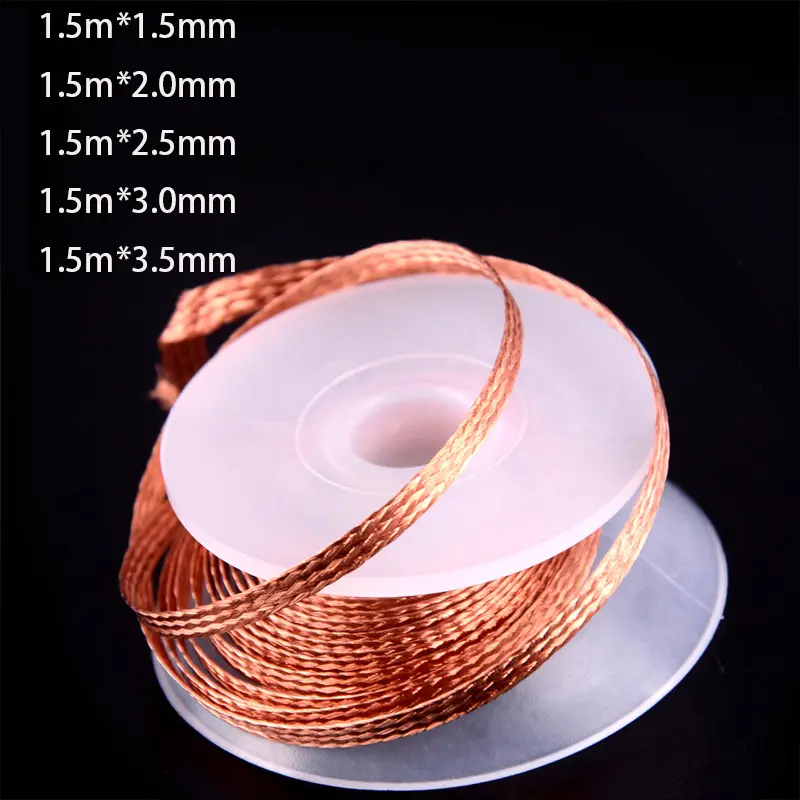

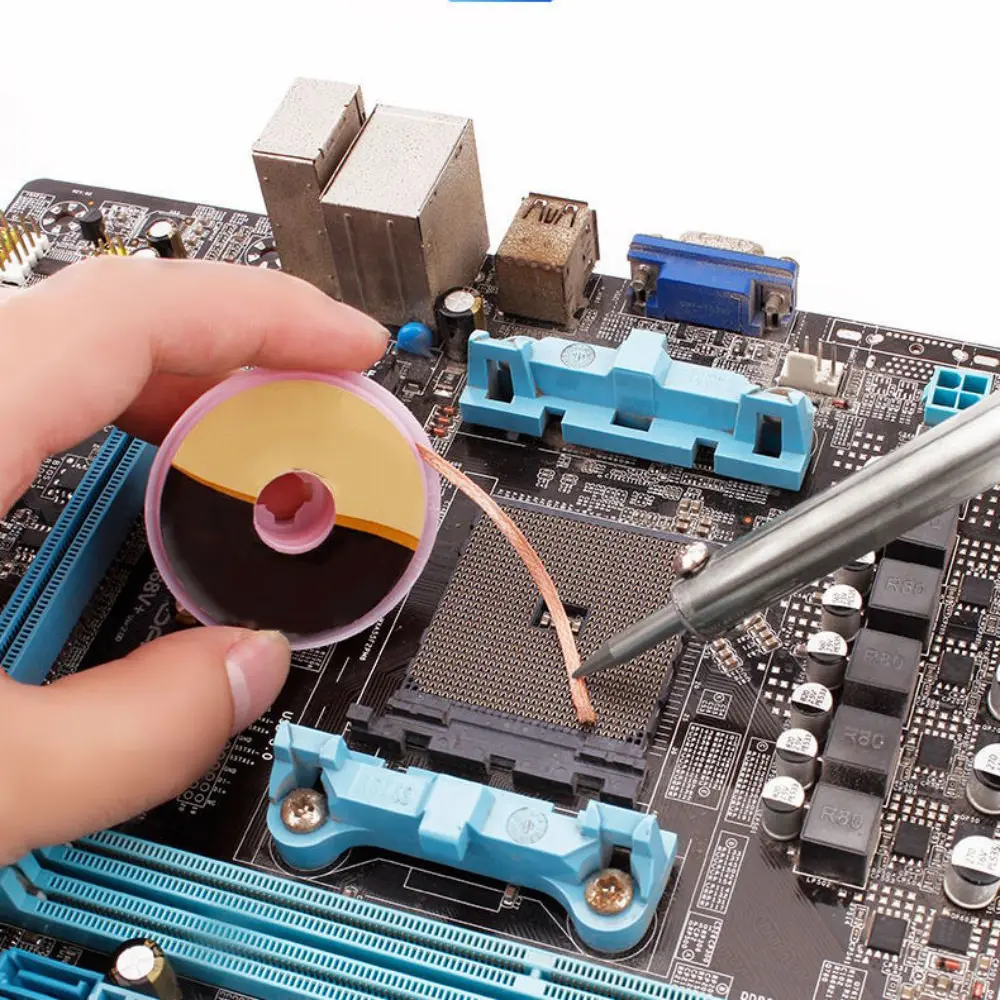

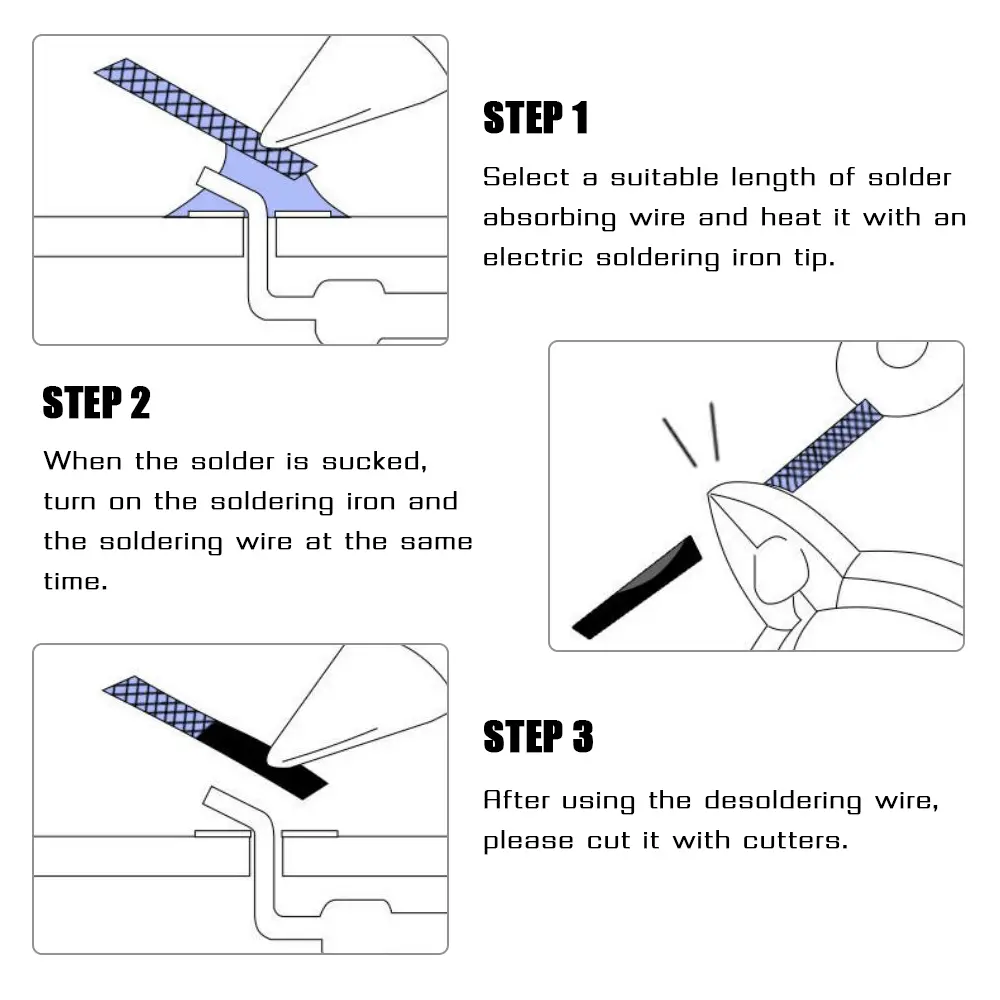

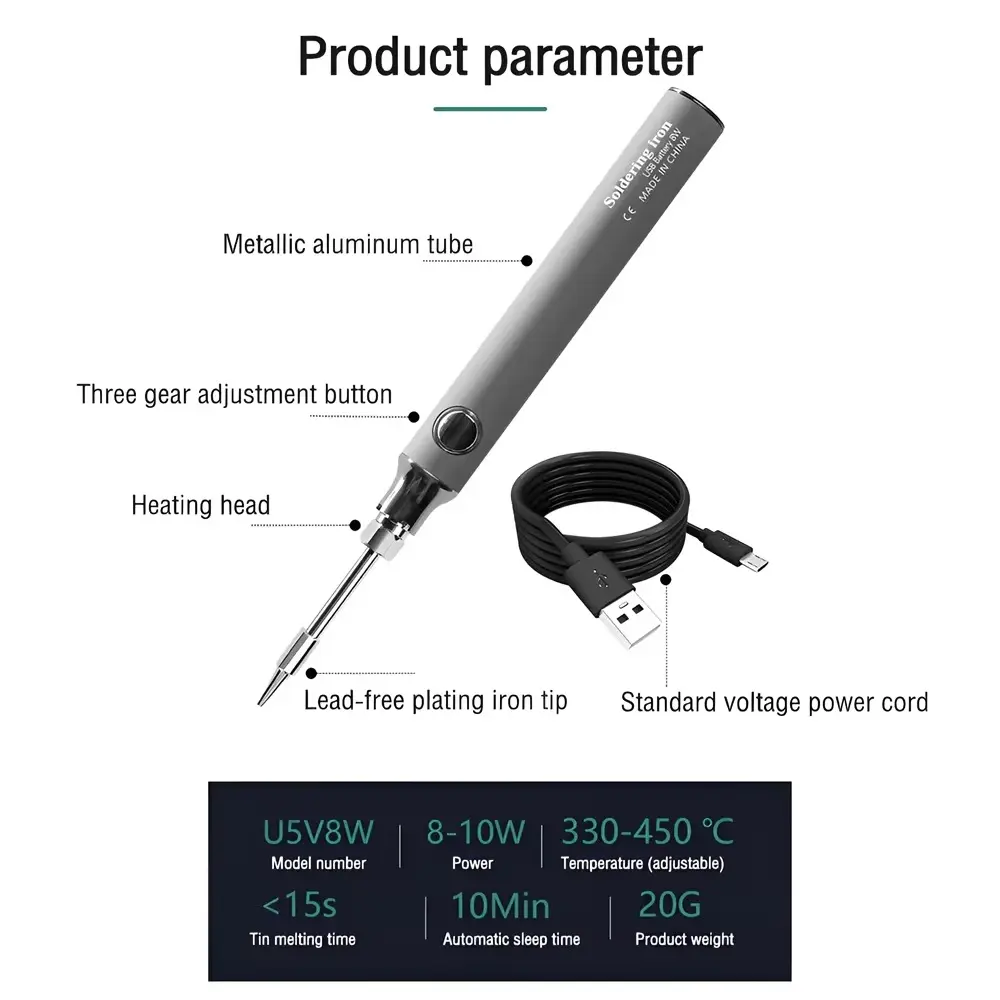

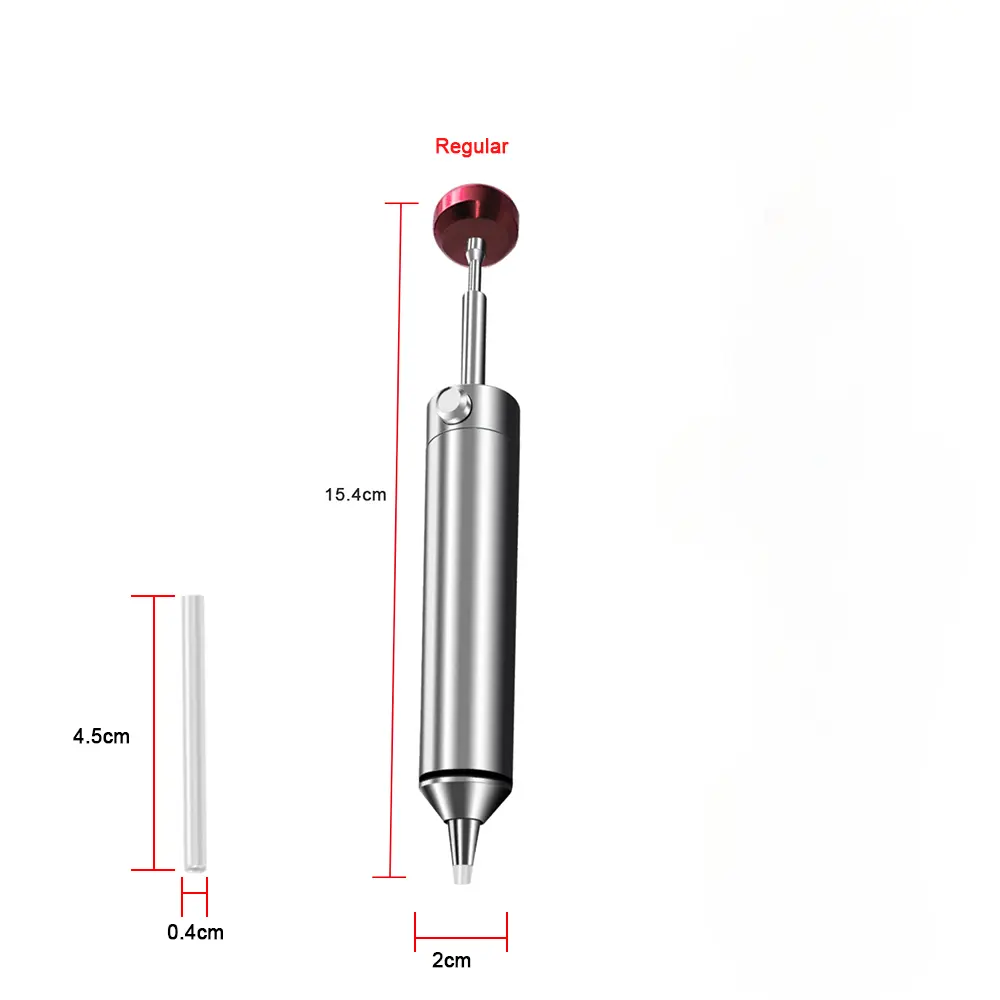

<p><kse:widget data-widget-type="customText" id="1005000000567623" type="relation"></kse:widget></p><p><strong><span style="font-size:20px">Electric Vacuum Solder Sucker Welding Desoldering Pump Soldering Iron Removal Solder Iron Pen Welding Repair Tool</span></strong></p><p><br/></p><p><span style="font-size:18px"><strong>Product Description and Features:</strong></span></p><p><span style="font-size:18px">(Description) The thermal dual-purpose tin suction device has the characteristics of beautiful appearance, novel structure, easy to use and clean tin suction. It can be used to easily remove the components to be replaced from the circuit board without damaging the components and the circuit board. . The advantages of replacing integrated circuits and multi-foot switches are more prominent. This tin suction device can be used as a general electric soldering iron, and it is an essential tool for national defense, scientific research, communication, aerospace, computer, radio, television, electronic professional maintenance personnel and radio enthusiasts.</span></p><p><br/></p><p><span style="font-size:18px">Solder suction is very practical for beginners. It is always easy to get solder everywhere when using an electric soldering iron for the first time. Solder suction can help you get rid of excess solder on the circuit board. In addition, the solder suction machine is very useful when removing components. It can suck off all the solder joints. You can do some small repairs yourself. If it needs to be replaced, or the tin in the PCB hole cannot be removed, at this time, we definitely recommend that you buy a tin absorber. Ordinary tin suckers do not have heating and need to be used in conjunction with an electric soldering iron. The tin can be washed and sucked off when the electric soldering iron melts the solder, while the electric tin sucker can complete the two functions of heating and sucking tin at the same time with one hand. It can also be used as an ordinary soldering iron when it is not needed to absorb tin. When using, first heat the solder, and then press the trigger of the tin remover to solve it at one time.</span></p><p><span style="font-size:18px">(feature)</span></p><p><span style="font-size:18px">1. Compact size</span></p><p><span style="font-size:18px">2. Pure copper power cord</span></p><p><span style="font-size:18px">3. Sensitive trigger switch</span></p><p><span style="font-size:18px">4. Seamless stainless steel tube</span></p><p><span style="font-size:18px">5. Full metal nozzle</span></p><p><span style="font-size:18px">6. High temperature nylon handle</span></p><p><span style="font-size:18px">7. Tin melting + tin removal, one-handed operation</span></p><p><span style="font-size:18px">8. The electric dual-purpose vacuum cleaner has the characteristics of beautiful appearance, novel structure and convenient use.</span></p><p><span style="font-size:18px">9. All solder joints can be easily sucked out, and the components that need to be replaced can be removed from the circuit board without damaging the components and the circuit board.</span></p><p><span style="font-size:18px">10. It is very convenient to replace integrated circuits and multi-foot switches</span></p><p><span style="font-size:18px">11. The two steps of one-hand heating and tin removal can be completed at the same time, which can accurately absorb tin and melt, and take out the parts smoothly.</span></p><p><span style="font-size:18px">12. It can be used as a general-purpose soldering iron, and it is a necessary tool for national defense, scientific research, communication, aerospace, computer, radio, television, electronic professional maintenance personnel and radio enthusiasts.</span></p><p><br/></p><p><span style="font-size:18px"><strong>Product Specifications:</strong></span></p><p><span style="font-size:18px">Working voltage: 220V</span></p><p><span style="font-size:18px">Power: 30W</span></p><p><span style="font-size:18px">Suction: 40CM/HG</span></p><p><span style="font-size:18px">Size: as shown</span></p><p><br/></p><p><span style="font-size:18px"><strong>Instructions:</strong></span></p><p><span style="font-size:18px">1. The voltage of the tin suction device is 220V-50Hz, and the power is 30W</span></p><p><span style="font-size:18px">2. Turn on the power and preheat for 3-5 minutes</span></p><p><span style="font-size:18px">3. Push the piston handle down and jam it, and align the front end of the suction nozzle of the soldering iron with the solder joint of the component to be removed. After the solder is melted, press the control button, and the solder will be sucked into the air cylinder.</span></p><p><span style="font-size:18px">Fourth, the tin suction device is equipped with two suction nozzles with different diameters, which can be selected according to the thickness of the component leads</span></p><p><span style="font-size:18px">5. When welding, the same operation as using an electric soldering iron</span></p><p><span style="font-size:18px">6. When disassembling the air cylinder, press down the upper end of the air cylinder in the direction of the arrow, and pull the air cylinder and the handle apart at the same time, and the air cylinder can be separated. Notes on removal</span></p><p><span style="font-size:18px">1. Check whether the voltage used is consistent, too high or too low voltage is not conducive to use</span></p><p><span style="font-size:18px">2. Tighten the suction nozzle and air cylinder before use to prevent air leakage, otherwise it will affect the tin suction effect</span></p><p><span style="font-size:18px">3. Always remove the solder impurities entering the suction nozzle and the air cylinder, and add a little oil to the piston</span></p><p><span style="font-size:18px">4. After each use, push the piston 3-4 times to remove the residual solder in the suction tube, so that the suction nozzle and the suction tube are unobstructed, so as to facilitate the next use</span></p><p><span style="font-size:18px">5. After the tin suction device is powered on, it is strictly forbidden to install and disassemble its electric heating parts.</span></p><p><span style="font-size:18px">6. When the new tin suction device is used for the first time, it may smoke slightly due to the heating of the electric heating element. This is a normal phenomenon, and it will disappear naturally after ten minutes.</span></p><p><span style="font-size:18px">Seven, in the process of use, must be equipped with a soldering iron holder with a natural heat dissipation structure and should be placed in the soldering iron holder</span></p><p><span style="font-size:18px">8. If the power cord is damaged, in order to avoid danger, it must be replaced by the manufacturer or its maintenance department or similar full-time personnel</span></p><p><span style="font-size:18px">9. This product has a ground wire. It should be used with a socket with contacts. Please pay attention to the use of the product for safety.</span></p><p><br/></p><p><span style="font-size:18px"><strong>packing list:</strong></span></p><p><span style="font-size:18px">1 x Electric and Heater Solder Remover</span></p><p><br/></p>

$11.555

$7.64

- Category : Tools

- Brand : z_industry_store Z Industry Store

Colors

Sizes

-

+

<p><kse:widget data-widget-type="customText" id="1005000000567623" type="relation"></kse:widget></p><p><strong><span style="font-size:20px">Electric Vacuum Solder Sucker Welding Desoldering Pump Soldering Iron Removal Solder Iron Pen Welding Repair Tool</span></strong></p><p><br/></p><p><span style="font-size:18px"><strong>Product Description and Features:</strong></span></p><p><span style="font-size:18px">(Description) The thermal dual-purpose tin suction device has the characteristics of beautiful appearance, novel structure, easy to use and clean tin suction. It can be used to easily remove the components to be replaced from the circuit board without damaging the components and the circuit board. . The advantages of replacing integrated circuits and multi-foot switches are more prominent. This tin suction device can be used as a general electric soldering iron, and it is an essential tool for national defense, scientific research, communication, aerospace, computer, radio, television, electronic professional maintenance personnel and radio enthusiasts.</span></p><p><br/></p><p><span style="font-size:18px">Solder suction is very practical for beginners. It is always easy to get solder everywhere when using an electric soldering iron for the first time. Solder suction can help you get rid of excess solder on the circuit board. In addition, the solder suction machine is very useful when removing components. It can suck off all the solder joints. You can do some small repairs yourself. If it needs to be replaced, or the tin in the PCB hole cannot be removed, at this time, we definitely recommend that you buy a tin absorber. Ordinary tin suckers do not have heating and need to be used in conjunction with an electric soldering iron. The tin can be washed and sucked off when the electric soldering iron melts the solder, while the electric tin sucker can complete the two functions of heating and sucking tin at the same time with one hand. It can also be used as an ordinary soldering iron when it is not needed to absorb tin. When using, first heat the solder, and then press the trigger of the tin remover to solve it at one time.</span></p><p><span style="font-size:18px">(feature)</span></p><p><span style="font-size:18px">1. Compact size</span></p><p><span style="font-size:18px">2. Pure copper power cord</span></p><p><span style="font-size:18px">3. Sensitive trigger switch</span></p><p><span style="font-size:18px">4. Seamless stainless steel tube</span></p><p><span style="font-size:18px">5. Full metal nozzle</span></p><p><span style="font-size:18px">6. High temperature nylon handle</span></p><p><span style="font-size:18px">7. Tin melting + tin removal, one-handed operation</span></p><p><span style="font-size:18px">8. The electric dual-purpose vacuum cleaner has the characteristics of beautiful appearance, novel structure and convenient use.</span></p><p><span style="font-size:18px">9. All solder joints can be easily sucked out, and the components that need to be replaced can be removed from the circuit board without damaging the components and the circuit board.</span></p><p><span style="font-size:18px">10. It is very convenient to replace integrated circuits and multi-foot switches</span></p><p><span style="font-size:18px">11. The two steps of one-hand heating and tin removal can be completed at the same time, which can accurately absorb tin and melt, and take out the parts smoothly.</span></p><p><span style="font-size:18px">12. It can be used as a general-purpose soldering iron, and it is a necessary tool for national defense, scientific research, communication, aerospace, computer, radio, television, electronic professional maintenance personnel and radio enthusiasts.</span></p><p><br/></p><p><span style="font-size:18px"><strong>Product Specifications:</strong></span></p><p><span style="font-size:18px">Working voltage: 220V</span></p><p><span style="font-size:18px">Power: 30W</span></p><p><span style="font-size:18px">Suction: 40CM/HG</span></p><p><span style="font-size:18px">Size: as shown</span></p><p><br/></p><p><span style="font-size:18px"><strong>Instructions:</strong></span></p><p><span style="font-size:18px">1. The voltage of the tin suction device is 220V-50Hz, and the power is 30W</span></p><p><span style="font-size:18px">2. Turn on the power and preheat for 3-5 minutes</span></p><p><span style="font-size:18px">3. Push the piston handle down and jam it, and align the front end of the suction nozzle of the soldering iron with the solder joint of the component to be removed. After the solder is melted, press the control button, and the solder will be sucked into the air cylinder.</span></p><p><span style="font-size:18px">Fourth, the tin suction device is equipped with two suction nozzles with different diameters, which can be selected according to the thickness of the component leads</span></p><p><span style="font-size:18px">5. When welding, the same operation as using an electric soldering iron</span></p><p><span style="font-size:18px">6. When disassembling the air cylinder, press down the upper end of the air cylinder in the direction of the arrow, and pull the air cylinder and the handle apart at the same time, and the air cylinder can be separated. Notes on removal</span></p><p><span style="font-size:18px">1. Check whether the voltage used is consistent, too high or too low voltage is not conducive to use</span></p><p><span style="font-size:18px">2. Tighten the suction nozzle and air cylinder before use to prevent air leakage, otherwise it will affect the tin suction effect</span></p><p><span style="font-size:18px">3. Always remove the solder impurities entering the suction nozzle and the air cylinder, and add a little oil to the piston</span></p><p><span style="font-size:18px">4. After each use, push the piston 3-4 times to remove the residual solder in the suction tube, so that the suction nozzle and the suction tube are unobstructed, so as to facilitate the next use</span></p><p><span style="font-size:18px">5. After the tin suction device is powered on, it is strictly forbidden to install and disassemble its electric heating parts.</span></p><p><span style="font-size:18px">6. When the new tin suction device is used for the first time, it may smoke slightly due to the heating of the electric heating element. This is a normal phenomenon, and it will disappear naturally after ten minutes.</span></p><p><span style="font-size:18px">Seven, in the process of use, must be equipped with a soldering iron holder with a natural heat dissipation structure and should be placed in the soldering iron holder</span></p><p><span style="font-size:18px">8. If the power cord is damaged, in order to avoid danger, it must be replaced by the manufacturer or its maintenance department or similar full-time personnel</span></p><p><span style="font-size:18px">9. This product has a ground wire. It should be used with a socket with contacts. Please pay attention to the use of the product for safety.</span></p><p><br/></p><p><span style="font-size:18px"><strong>packing list:</strong></span></p><p><span style="font-size:18px">1 x Electric and Heater Solder Remover</span></p><p><br/></p>

Related Product

Browse The Collection of Top Products.