Stepper motor set, plc motion control, encoder drive proximity switch, screw slide table, module

<div class="detailmodule_html"><div class="detail-desc-decorate-richtext"><div class="detailmodule_text-image">

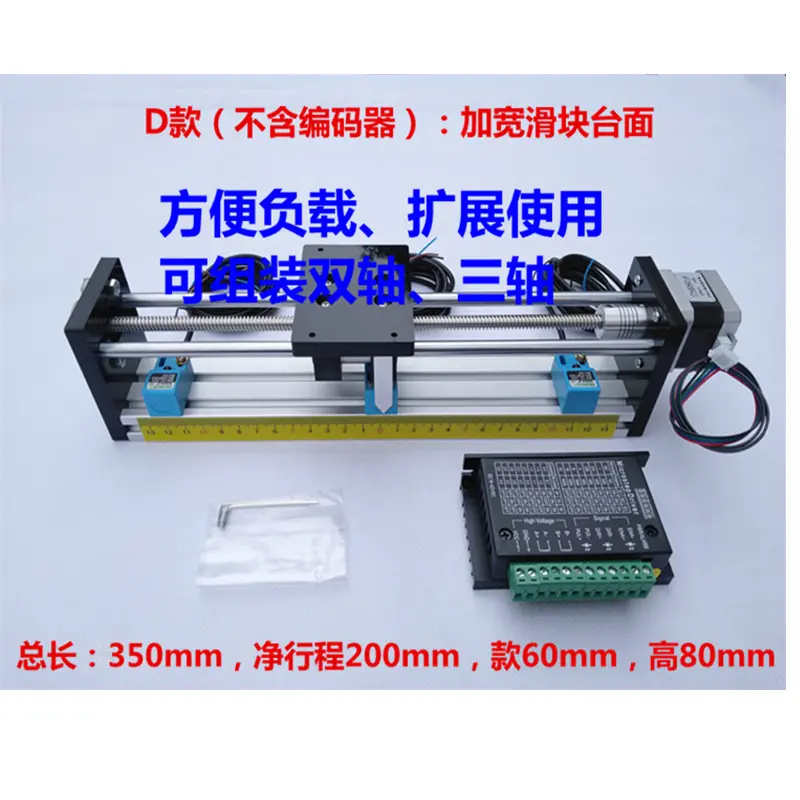

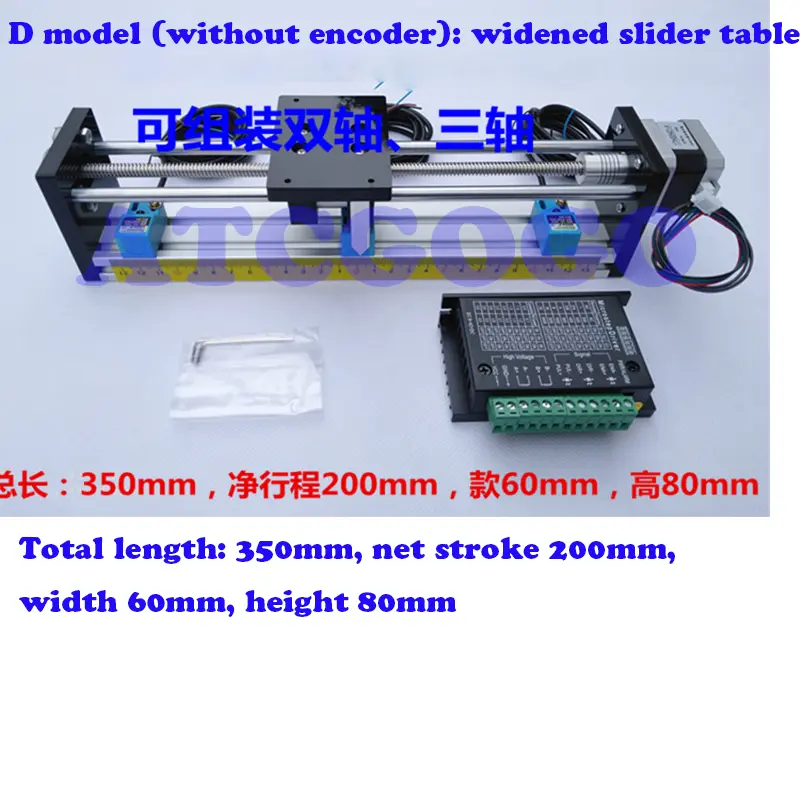

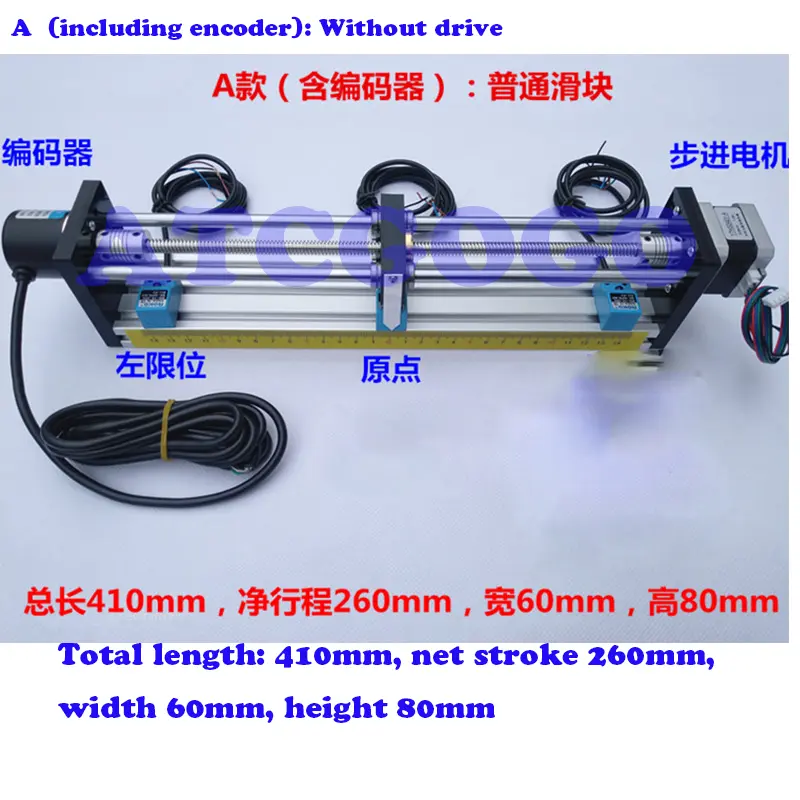

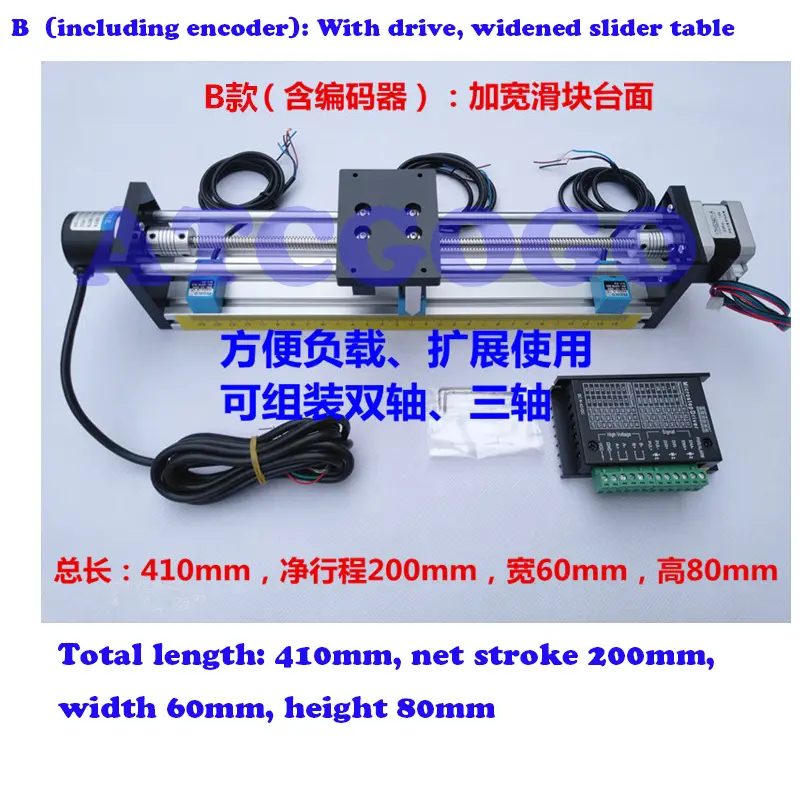

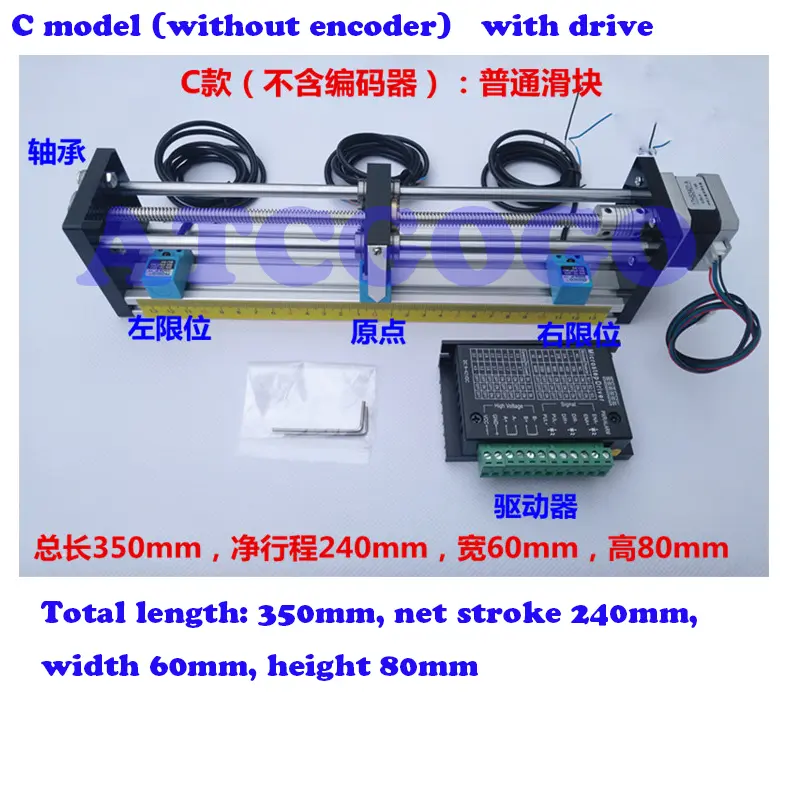

<p class="detail-desc-decorate-content" style="text-overflow: ellipsis;font-family: 'OpenSans';color:'#000';word-wrap: break-word;white-space: pre-wrap;font-weight: 300;font-size: 14px;line-height: 20px;color: #000;margin-bottom: 12px;">1. The sliding table is equipped with a 42 stepper motor by default. If you don't need a motor, please contact customer service before buying 2. The sliding table can be equipped with a servo motor within 100w. If you use a self-equipped servo motor, you need to provide a detailed dimensional drawing of the motor used. We can customize the flange mounting plate of the sliding table according to your motor size. 3. Product screw specifications: shaft diameter 8mm, lead 4mm, stroke 260mm (manual measurement, a little error) 4. This sliding table can be assembled with multiple axes: cross sliding table, gantry type, three-axis. . . 5. Customers can customize non-standard products, we are professional and have strong strength to meet your needs 6. The black baffles at both ends and the middle slider are made of high-strength acrylic, which has good linearity, lightness and durability, anti-rust, and comparable to metal materials. (For details, please contact customer service. Note: Once the customized product is produced, it cannot be returned) 1. Stepping motor current: 1.2-1.5A, step angle 1.8°200 pulses/turn. 2. Stepper motor wiring: red A+ blue A- green B+ black B- 3. Screw pitch of sliding table: 4MM/circle 4. Sensor type: three-wire system, default delivery NPN normally open (NPN, PNP type can be selected) 5. Sensor wiring: brown 24+ blue 24-black (signal output) 6. Encoder type: photoelectric incremental AB two-phase 600 pulse, default delivery NPN 7. Encoder wiring: red 24+ black 24-white A pulse green B pulse 8. Driver description: The pulse direction enable port does not require series resistance Note: The motor current is set strictly in accordance with the given parameters and corresponds to the current set by the drive. The maximum speed of the stepping motor is 600 rpm. For the first commissioning, the number of pulses should not exceed the maximum speed of the motor after calculation About limit sensor (proximity type) NPN type sensor outputs low-level signal when sensing PNP type sensor outputs high level signal when sensing When Siemens PLC uses NPN type sensor and encoder, the common end of the input point (1M...) is connected to 24+1, and the sliding table is equipped with 42 stepper motors by default. If you do not need a motor, please contact customer service before purchasing 2. The sliding table can be equipped with a servo motor within 100w. If you use a self-equipped servo motor, you need to provide a detailed dimensional drawing of the motor used. We can customize the flange mounting plate of the sliding table according to your motor size. 3. Product screw specifications: shaft diameter 8mm, lead 4mm, stroke 260mm (manual measurement, a little error) 4. This sliding table can be assembled with multiple axes: cross sliding table, gantry type, three-axis. . . 5. Customers can customize non-standard products, we are professional and have strong strength to meet your needs 6. The black baffles at both ends and the middle slider are made of high-strength acrylic, which has good linearity, lightness and durability, anti-rust, and comparable to metal materials. (For details, please contact customer service. Note: Once the customized product is produced, it cannot be returned) 1. Stepping motor current: 1.2-1.5A, step angle 1.8°200 pulses/turn. 2. Stepper motor wiring: red A+ blue A- green B+ black B- 3. Screw pitch of sliding table: 4MM/circle 4. Sensor type: three-wire system, default delivery NPN normally open (NPN, PNP type can be selected) 5. Sensor wiring: brown 24+ blue 24-black (signal output) 6. Encoder type: photoelectric incremental AB two-phase 600 pulse, default delivery NPN 7. Encoder wiring: red 24+ black 24-white A pulse green B pulse 8. Driver description: The pulse direction enable port does not require series resistance Note: The motor current is set strictly in accordance with the given parameters and corresponds to the current set by the drive. The maximum speed of the stepping motor is 600 rpm. For the first commissioning, the number of pulses should not exceed the maximum speed of the motor after calculation About limit sensor (proximity type) NPN type sensor outputs low-level signal when sensing PNP type sensor outputs high level signal when sensing When Siemens PLC uses NPN type sensor and encoder, the common end (1M...) of the input point is connected to 24+</p>

</div></div></div>

$104.435

$104.435

- Category : Home Improvement

- Brand : gogoatc_hydraulic_store GOGOATC HYDRAULIC Store

Colors

Sizes

-

+

<div class="detailmodule_html"><div class="detail-desc-decorate-richtext"><div class="detailmodule_text-image">

<p class="detail-desc-decorate-content" style="text-overflow: ellipsis;font-family: 'OpenSans';color:'#000';word-wrap: break-word;white-space: pre-wrap;font-weight: 300;font-size: 14px;line-height: 20px;color: #000;margin-bottom: 12px;">1. The sliding table is equipped with a 42 stepper motor by default. If you don't need a motor, please contact customer service before buying 2. The sliding table can be equipped with a servo motor within 100w. If you use a self-equipped servo motor, you need to provide a detailed dimensional drawing of the motor used. We can customize the flange mounting plate of the sliding table according to your motor size. 3. Product screw specifications: shaft diameter 8mm, lead 4mm, stroke 260mm (manual measurement, a little error) 4. This sliding table can be assembled with multiple axes: cross sliding table, gantry type, three-axis. . . 5. Customers can customize non-standard products, we are professional and have strong strength to meet your needs 6. The black baffles at both ends and the middle slider are made of high-strength acrylic, which has good linearity, lightness and durability, anti-rust, and comparable to metal materials. (For details, please contact customer service. Note: Once the customized product is produced, it cannot be returned) 1. Stepping motor current: 1.2-1.5A, step angle 1.8°200 pulses/turn. 2. Stepper motor wiring: red A+ blue A- green B+ black B- 3. Screw pitch of sliding table: 4MM/circle 4. Sensor type: three-wire system, default delivery NPN normally open (NPN, PNP type can be selected) 5. Sensor wiring: brown 24+ blue 24-black (signal output) 6. Encoder type: photoelectric incremental AB two-phase 600 pulse, default delivery NPN 7. Encoder wiring: red 24+ black 24-white A pulse green B pulse 8. Driver description: The pulse direction enable port does not require series resistance Note: The motor current is set strictly in accordance with the given parameters and corresponds to the current set by the drive. The maximum speed of the stepping motor is 600 rpm. For the first commissioning, the number of pulses should not exceed the maximum speed of the motor after calculation About limit sensor (proximity type) NPN type sensor outputs low-level signal when sensing PNP type sensor outputs high level signal when sensing When Siemens PLC uses NPN type sensor and encoder, the common end of the input point (1M...) is connected to 24+1, and the sliding table is equipped with 42 stepper motors by default. If you do not need a motor, please contact customer service before purchasing 2. The sliding table can be equipped with a servo motor within 100w. If you use a self-equipped servo motor, you need to provide a detailed dimensional drawing of the motor used. We can customize the flange mounting plate of the sliding table according to your motor size. 3. Product screw specifications: shaft diameter 8mm, lead 4mm, stroke 260mm (manual measurement, a little error) 4. This sliding table can be assembled with multiple axes: cross sliding table, gantry type, three-axis. . . 5. Customers can customize non-standard products, we are professional and have strong strength to meet your needs 6. The black baffles at both ends and the middle slider are made of high-strength acrylic, which has good linearity, lightness and durability, anti-rust, and comparable to metal materials. (For details, please contact customer service. Note: Once the customized product is produced, it cannot be returned) 1. Stepping motor current: 1.2-1.5A, step angle 1.8°200 pulses/turn. 2. Stepper motor wiring: red A+ blue A- green B+ black B- 3. Screw pitch of sliding table: 4MM/circle 4. Sensor type: three-wire system, default delivery NPN normally open (NPN, PNP type can be selected) 5. Sensor wiring: brown 24+ blue 24-black (signal output) 6. Encoder type: photoelectric incremental AB two-phase 600 pulse, default delivery NPN 7. Encoder wiring: red 24+ black 24-white A pulse green B pulse 8. Driver description: The pulse direction enable port does not require series resistance Note: The motor current is set strictly in accordance with the given parameters and corresponds to the current set by the drive. The maximum speed of the stepping motor is 600 rpm. For the first commissioning, the number of pulses should not exceed the maximum speed of the motor after calculation About limit sensor (proximity type) NPN type sensor outputs low-level signal when sensing PNP type sensor outputs high level signal when sensing When Siemens PLC uses NPN type sensor and encoder, the common end (1M...) of the input point is connected to 24+</p>

</div></div></div>